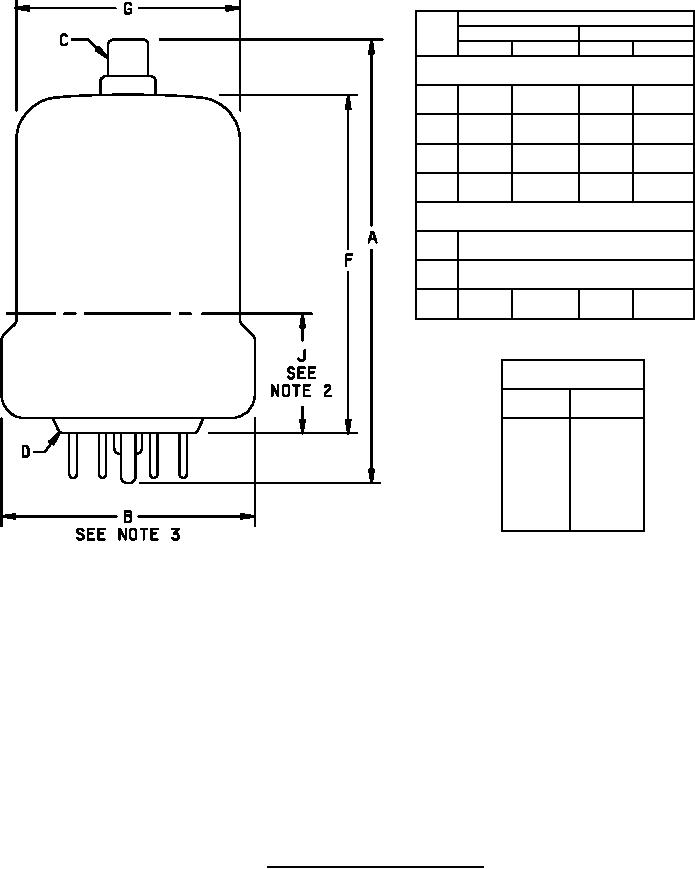

MIL-PRF-1/876G

Dimensions

Ltr

Inches

Millimeters

Min

Max

Min

Max

Conformance inspection, part 2

A

4.000

4.375

101.60

111.13

B

---

2.375

---

60.33

G

---

2.060

---

52.32

J

.844

1.219

21.44

30.96

Conformance inspection, part 3 (see note 4)

C

Cap: C1-22 (EIA) (See note 5)

D

Base: E5-59 (See note 2) (EIA)

F

2.938

3.313

74.63

84.15

Pin connections

Pin No.

Element

1

f

2

g2

4

g1

6

g2

7

f

Cap

a

NOTES:

1. For pin alignment, use JEDEC gauge GE7-6. A molded glass flare base with pin configuration identical with that of base E5-59

may be used.

2. With base pins inserted into gauge GE7-6, a flat plate gauge with a 2.063 ± .003 inches (52.40 ± 0.08 mm) diameter hole is

passed over diameter G until it stops at position defined by dimension J. Dimension J shall then be gauged between bottom

surface of flat-plate gauge and top surface of gauge GE7-6 with surfaces of both gauges parallel. The 2.063 inches (52.40 mm)

diameter hole of the flat-plate gauge and .500 inch (12.70 mm) diameter hole of gauge GE7-6 shall be concentric within .150 inch

(3.81 mm).

3. A ring gauge .125 ± .010 inch (3.18 ± 0.26 mm) thick and 2.125 inches (53.98 mm) minimum and 2.128 inches (54.05 mm)

maximum inside diameter shall not pass over diameter B when tried at an angle.

4. Dimensions shall be checked yearly. An accept on zero defect sampling plan shall be used on a sample of three tubes. In the

event of failure, the test will be made as a part of conformance inspection, part 2, in accordance with the accept on zero (c=0)

sampling plan of MIL-PRF-1, Table III, for category XV. The regular yearly sampling plan may be reinstated after three

consecutive samples have been accepted.

5. In the referenced EIA standard Cap C1-22, the dimension .656" MIN should be .328" MIN.

FIGURE 1. Outline drawing of electron tube type 8165.

4