MIL-PRF-1/746H

Dimensions

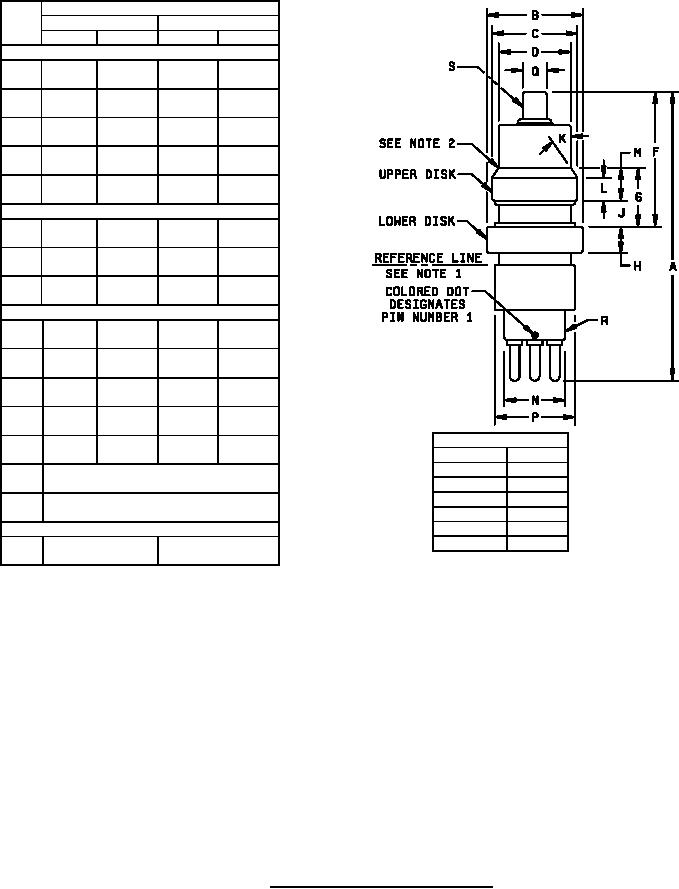

Ltr

Inches

Millimeters

Min

Max

Min

Max

Conformance inspection, part 1

A

2.969

3.219

75.41

81.76

B

.990

1.000

25.15

25.40

C

.880

.890

22.35

22.61

F

1.375

1.500

34.93

38.10

M

.303

.323

7.70

8.20

Conformance inspection, part 2

G

.560

.610

14.22

15.49

H

.250

.312

6.35

7.92

J

.257

.287

6.53

7.29

Conformance inspection, part 3

D

---

.750

---

19.05

25°

35°

25°

35°

K

N

.610

.656

15.49

16.66

P

.807

.822

20.50

20.88

Pin connections

1

g1

Q

.245

.255

6.22

6.48

2

h

3

k

R

Base: A4-76

4

h

Lower disk

g2

S

Cap: C1-3

Upper disk

g3

Nominal dimensions

Cap

r

L

.250

6.35

NOTES:

1. For dimensions below reference line refer to base A4-76.

`

2.

Space between glass and upper disk edge or backing ring shall be .030 inch (0.76 mm) maximum. Conformance inspection,

part 2, shall apply.

3.

Diameters B and C shall be concentric within .025 inch (0.63 mm) TIR and shall form circular cylinder within a range of .006

inch (0.15 mm). Allowable radius at ends of cylinder shall be .030 inch (0.76 mm) maximum. Conformance inspection, part

2, shall apply.

4.

Tube shall be tested in concentricity gauge specified on drawing 199-JAN. Gauge readings on diameters shall be as follows:

Diameter

Eccentricity

D

.050 max

N

.060 max

P

.060 max

Q

.040 max

5.

All concentricity measurements shall be conformance inspection, part 2.

6.

Pin No. 1 shall be identified by an index mark (colored dot or other.)

FIGURE 1. Outline drawing of electron tube type 6BMA.

4