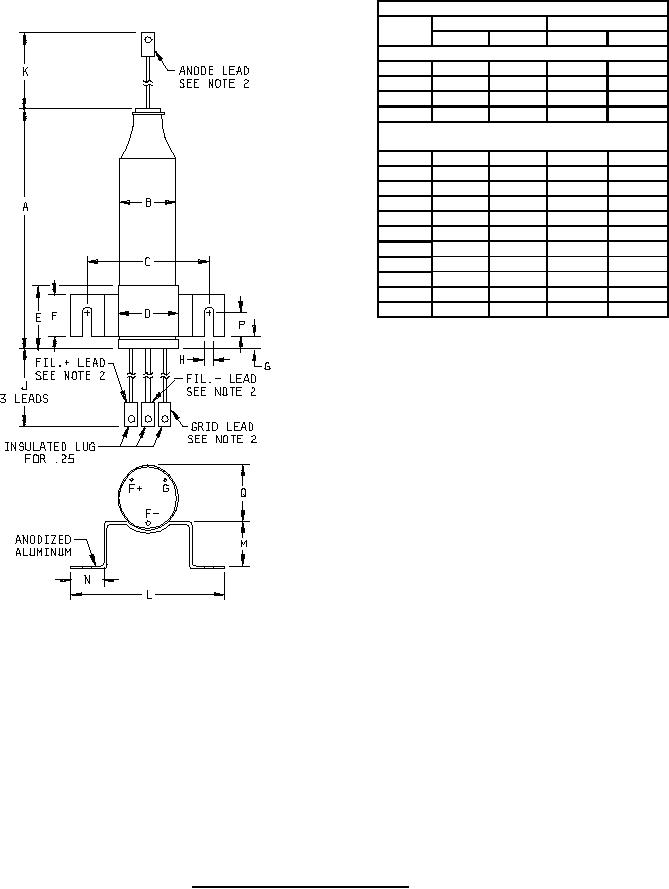

MIL-PRF-1/664F

Dimensions

Ltr

Inches

Millimeter

Min

Max

Min

Max

Conformance inspection, part 2

A

9.500

10.500

241.30

266.70

B

2.375

2.750

60.32

69.85

C

4.875

5.125

123.82

130.18

M

1.437

1.687

36.50

42.85

Conformance inspection, part 3

(see note 4)

D

2.562

2.812

65.07

71.42

E

2.562

2.687

65.07

68.25

F

1.687

1.812

42.85

46.02

G

.437

.562

11.10

14.27

H

.312

.437

7.92

11.10

J

5.375

5.875

136.52

149.22

K

7.250

7.750

184.15

196.85

L

6.375

6.625

161.92

168.28

N

1.562

1.812

39.67

46.02

P

.812

.937

20.62

23.80

Q

2.187

2.437

55.55

61.90

NOTES:

1. Use of ceramic beads or fiber glass sleeves with silicone resin impregnation as lead insulators is optional.

2. Leads:

Flexible; silicone-impregnated glass fiber insulation, class C-2 or better; as follows: (see notes 3 and 5)

Anode:

at top; lug for .25 inch nominal (6.4 mm) stud, lug width .41 inch nominal (10.4 mm).

Fil. +:

at base; insulated lug for .25 inch nominal (6.4 mm) stud, lug width .47 inch nominal (11.9 mm).

Fil. - :

at base; insulated lug for .25 inch nominal (6.4 mm) stud, lug width .41 inch nominal (10.4 mm).

Grid:

at base; insulated lug for .25 inch nominal (6.4 mm) stud, lug width .47 inch nominal (11.9 mm).

3. Each lead shall be clearly marked as specified herein.

FIGURE 1. Outline drawing of electron tube type 5665.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business