MIL-PRF-1/505H

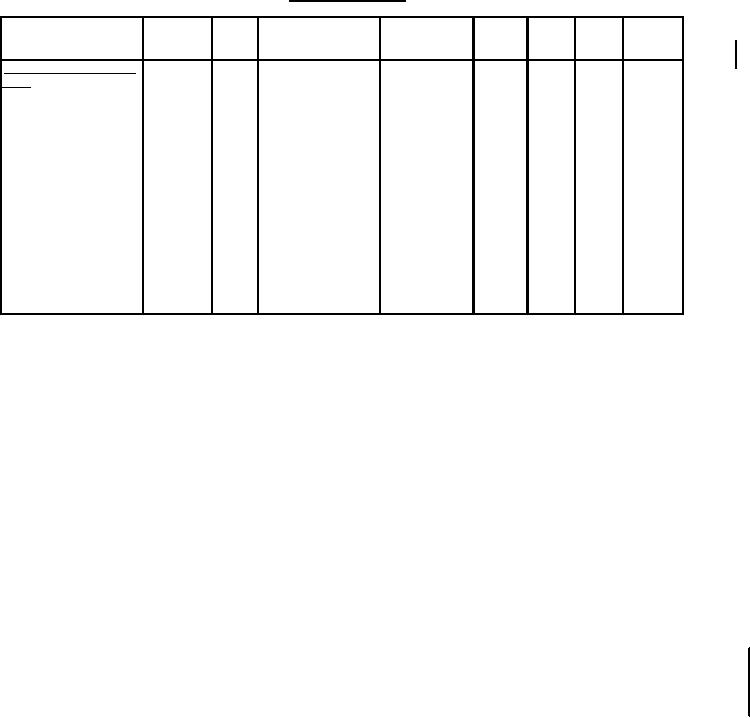

TABLE 1. Testing and inspection - Continued.

Inspection

Method

Notes

Conditions

Acceptance

Symbol

Limits

Limits

Units

MIL-STD-

Level

Min

Max

1311

(see note 8)

Conformance inspection,

part 3

---

---

---

---

---

Life test

---

Group B; Ebb/IB = 55

---

± 5 µA dc

t = 500 hours

Life-test end points:

---

V dc

715

685

Eb(1)

---

Voltage drop

3337

---

V dc

15

---

---

Regulation

3335

---

ĆEb

V dc

730

---

---

Ionization voltage

3347

---

Ez

---

---

---

---

Peak current

---

---

---

---

---

---

---

1041

Shock

2, 7

---

300 G

---

---

---

---

1002

7

Barometric pressure,

---

Pressure = 55 mmHg;

reduced

Eb = 750 V dc

NOTES:

1. Criterion for passing this test shall be compliance after test with the initial requirements for voltage drop and regulation.

2. Electrical samples shall not be used for this test. Ten additional samples shall be submitted for shock test only. Criterion for

passing this test shall be compliance after test of at least 80 percent of the tubes with the initial requirements for voltage drop

and regulation.

3. The tube under test shall not have been conducting for at least 30 minutes prior to test. During this test, the regulator tube shall

not be exposed to external sources of radiation and shall be shielded from light. No conditioning current is permitted.

4. ĆEb maximum shall not be exceeded anywhere within the range 5 to 55 µA dc. In testing for regulation, current shall be varied

continuously through the range of 5 to 55 µA dc.

5. Ebb shall be increased continuously until Ib = 200 µA dc. The voltage drop shall not go below its value at Ib = 55 µA dc.

6. The holding period commences upon completion of the initial performance of the specified tests. At the conclusion of the

holding period, the specified tests will be performed again. Of the tubes failing the holding period end-point tests, those which

fail with respect to voltage drop only, may be retested after an additional 30-day period. Eb(1) is the voltage drop measured at

the beginning of a holding period.

7. This test shall be performed during the initial production and once each succeeding 12-calendar months in which there is

production. An accept on zero defect sampling plan shall be used, with sample of three tubes with an acceptance number of

zero. In the event of failure, the test will be made as a part of conformance inspection, part 2, with an acceptance level of 6.5 (see

note 8). The "12-calendar month" sampling plan shall be reinstated after three consecutive samples have been accepted.

8. This specification sheet uses accept on zero defect sampling in accordance with MIL-PRF-1, table III.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business