MIL-PRF-1/501C

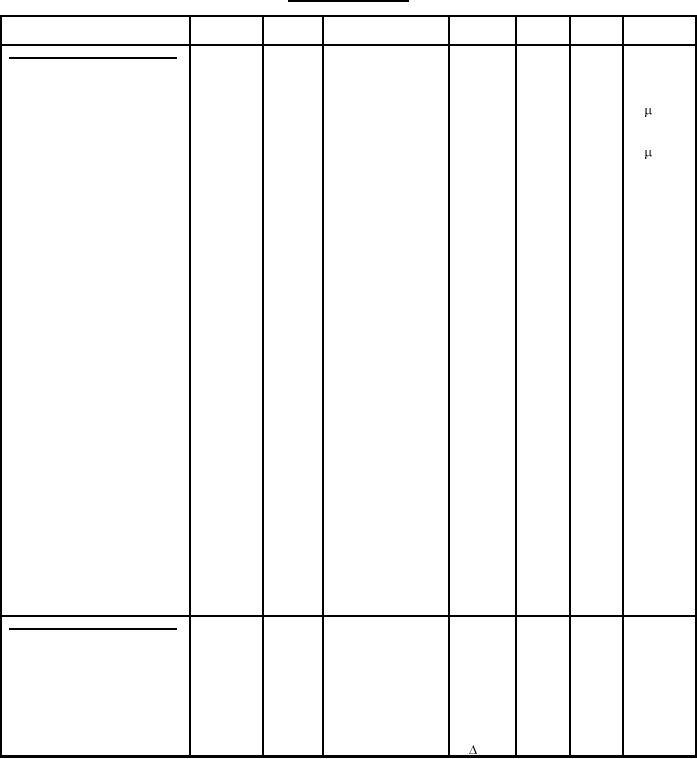

TABLE 1. Testing and inspection -Continued.

Inspection

Method

Notes

Conditions

Symbol

Limits

Limits

Units

Min

Max

Conformance inspection, part 2

Heater current

1301

---

If

540

660

mA

Electrode current

5201

---

Ec1 = 0

Ib1

-15

10

A dc

(anode No. 1)

Electrode current (cathode)

5201

---

Light = 4 fL

Ik

---

1,000

A dc

Base alignment

5101

---

+3D4; pin No. 1

---

---

---

---

(electrostatic types)

Angle between traces

5101

---

Angle

87

93

Degrees

Neck and base alignment

5101

---

---

---

---

---

(electrostatic types)

Stray light emission

5216

---

---

---

---

---

(conventional types)

Line width A

5226

---

Light = 4 fL

Width

---

0.4

mm

(electrostatic types)

Line width B

5226

---

Light = 4 fL

Width

---

0.4

mm

(electrostatic types)

Focusing voltage

---

---

Light = 4 fL

Eb1

240

450

V dc

Deflection factor

5248

---

1D2

DF

75

102

V dc/in.

Deflection factor

5248

---

3D4

DF

57

78

V dc/in.

Heater-cathode

5251

---

---

---

---

---

leakage current

Secureness of base,

1101

---

---

---

---

---

cap and insert

Base pin solder depth

1111

---

---

---

---

---

Permanence of marking

1105

---

---

---

---

---

Conformance inspection, part 3

---

---

---

---

Group C;

---

3

Life test

Light = 4 fL;

Eb2 = 2,750 V dc;

t = 500 hours (min)

---

Life-test end points:

mm

0.4

---

Width

Light = 3.4 fL

---

Line width A

mm

0.4

Width

---

Light = 3.4 fL

---

Line width B

V dc

45

---

Light = 3.4 fL

---

Modulation

Ec1

NOTES:

1. This test to be performed at the conclusion of the holding period.

2. This value is recommended only for low-velocity deflecting and low-ambient light levels.

3. During life-test operation the heater voltage shall be regularly interrupted on a 13 minutes "on", 7 minutes "off" cycle. Life test

minimum duration shall be the total of "on" plus "off" hours.

3