MIL-PRF-1/484E

NOTES:

1. These dimensions shall be checked on a lot-to-lot basis under conformance inspection, part 2 to an acceptance level of 6.5,

inspection level S3. The acceptance level is applied to each dimension separately and is not combined.

2. These dimensions shall be inspected at the start of production and periodically every 3 months during production. The

sample size shall be six tubes and the acceptance number shall be zero defects for each dimension. Failure of any

dimension to meet conformance inspection, part 3 requirements shall cause the nonconforming dimension to be inspection

on a lot-to-lot basis to a 6.5 acceptance level, inspection level S3. After three consecutive successful submissions, the

inspection shall revert to 3-month intervals.

3. All tubes are to be 100 percent tested for concentricity in gauge (see figure 3). Tube shall be rotated 360° in gauge without

binding.

4. Grid shell seal shall be completely filled to cathode ceramic shelf.

5. `T' dimension shall be measured other than across tube designation etch, and approximately .100 (2.54 mm) from the

reference plane.

6. `V' dimension shall be measured approximately .100 (2.54 mm) from the end of the anode terminal.

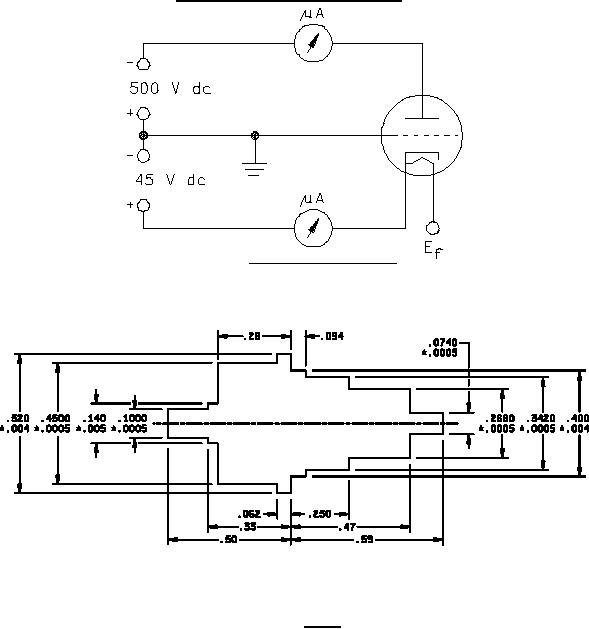

FIGURE 1. Outline drawing of electron tube type 6299 Continued.

FIGURE 2. Insulation of electrodes test.

NOTE: Unless otherwise specified, tolerance for dimension .250 or less ± .008; over .25 ± .02.

FIGURE 3. Gauge.

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business