MIL-PRF-1/484E

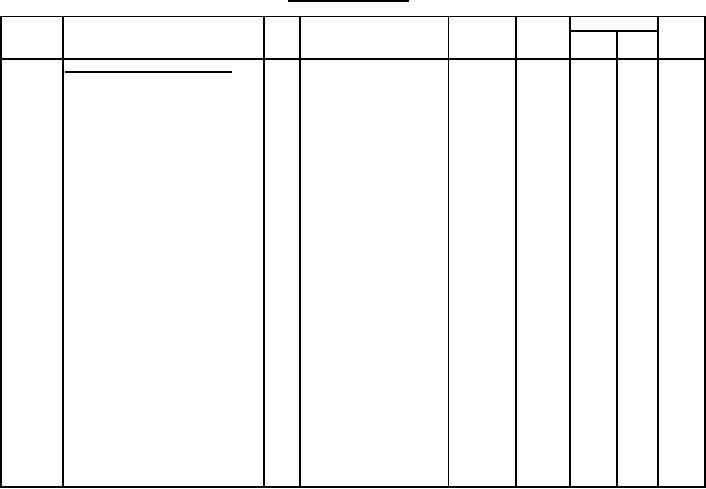

TABLE I. Testing and inspection- Continued.

Limits

MIL-STD-

Requirement or test

Notes

Conditions

Acceptance Symbol

Unit

1311

level

Min

Max

method

Conformance inspection, part 3

---

Life test

---

---

Group B;

---

---

---

---

Eb = 200 V dc;

Rk/Ib = 10 mA dc;

t = 1,000 hours

---

Life-test end points:

ĆSm

Transconductance

1306

---

---

25

%de-

---

crease

t

ĆNF

Noise figure (1)

---

---

---

1.0

dB in-

---

crease

t

Low-frequency vibration

1031

---

4

Ec = 0;

100

mVac

---

Ep

Eb/Ib = 10 mA dc;

Rp = 10,000 ohms;

Drawing 273-JAN

---

Shock

1041

5

---

No voltages; hammer

---

---

---

Angle=20°;

Drawing 274-JAN

Shock-test end points:

---

Sm

Transconductance

1306

---

11,500

---

µmhos

---

MegΩ

Rgp

Insulation of electrodes

1211

---

5.0

---

---

MegΩ

Rgk

Insulation of electrodes

1211

---

0.25

---

---

NOTES:

1.

The 60 Hz voltages eb and ec shall be in phase, and the sinusoidal waveform should not be distorted. Read average

cathode current.

2.

An approved noise source shall be used for noise figure measurements. Power input level shall be about -75 dBm for power

gain (1), noise figure (1), power gain (2), and noise figure (2).

3.

Envelope strain procedure. Tubes shall be tested as specified in MIL-STD-1311 method 2126, except that they shall first be

immersed in water at not more than 5°C for 15 seconds, and immediately thereafter subjected to the standard temperature

cycle specified in method 2126. The criteria for air leaks shall be heater current of 330 mA, or more.

4.

Vibrate in plane perpendicular to the plane of the grid. Test 10 tubes selected at random from the first production lot of each

calendar year, and approximately every 90 days of production during the year. If one tube fails to pass the specified end

points, the test shall become a part of conformance inspection, part 2, acceptance level of 6.5 (see note 6). After three

consecutive successful submissions, the test shall revert back to the 10-tube quarterly test.

5.

Apply the force perpendicular to the plane of the grid from the cathode end. Test 10 tubes selected at random from the first

production lot of each calendar year. If one tube fails to pass the specified endpoints, the test shall become a part of

conformance inspection, part 2, acceptance level of 6.5 (see note 6), on all lots in process. After three consecutive

successful submissions, the test shall revert back to a 10-tube annual test.

6.

This specification utilizes an accept on zero defect sampling plan in accordance with MIL-PRF-1, table III.

7.

Drawings 270-JAN, 271-JAN, 272-JAN, 273-JAN and 274-JAN are referenced herein. Contact the preparing activity for

availability information, if required."

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business