MIL-PRF-1/390E

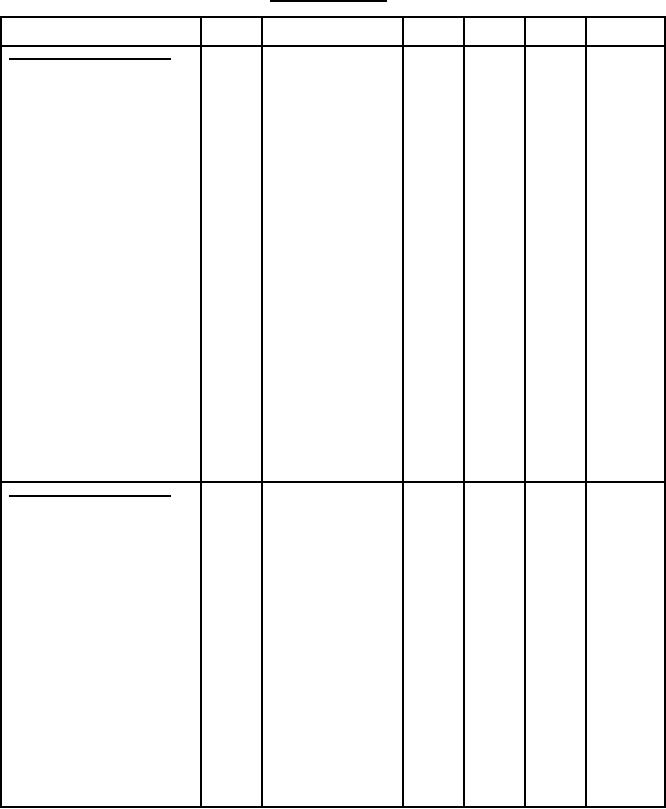

TABLE 1. Testing and inspection - Continued.

Inspection

Method

Conditions

Symbol

Limits

Limits

Unit

Min

Max

Conformance inspection, part 2

-Continued.

Neck and base alignment

5101

---

---

---

---

(electrostatic types)

Base and trace alignment

5101

+3D4; pin no. 1

---

---

---

---

Angle between traces

5101

---

---

---

---

Stray light emission

5216

Eb2 = 2,750 V dc

---

---

---

---

(conventional types)

Line width A (electrostatic

5226

Light = 4 fL

Width

---

mm

0.65

deflection)

Line width B (electrostatic

5226

Light = 4 fL

Width

---

mm

0.65

deflection)

Focusing voltage at cutoff

5246

Light = 4 fL

Eb1

165

V dc

310

Focusing voltage at modulation

5246

Eb1

165

V dc

310

condition

Deflection factor

5248

1D2

DF

73

V dc/inch

99

Deflection factor

5248

3D4

DF

52

V dc/inch

70

Heater-cathode leakage current

5251

---

---

---

---

Permanence of marking

1105

---

---

---

---

Conformance inspection, part 3

---

---

---

Group C; light = 4 fL;

---

---

Life test

Eb2 = 2,750 V dc;

T= 500 hours (min)

---

Light = 3.4 fL

---

---

---

---

Life-test end points:

0.65

Width

---

mm

Line width A

0.65

Width

---

mm

Line width B

ĆEc1

48

---

V dc

Modulation

---

---

---

Grid No. 1 leakage current

---

---

---

Anode No. 1 leakage current

---

---

---

---

Anode No. 2 leakage current

---

---

---

Heater-cathode leakage current

---

---

---

---

Stray light emission

---

---

---

NOTES:

1. This value is recommended only for low velocity deflecting and low ambient light levels.

2. This test to be performed at the conclusion of the holding period.

3