MIL-PRF-1/390E

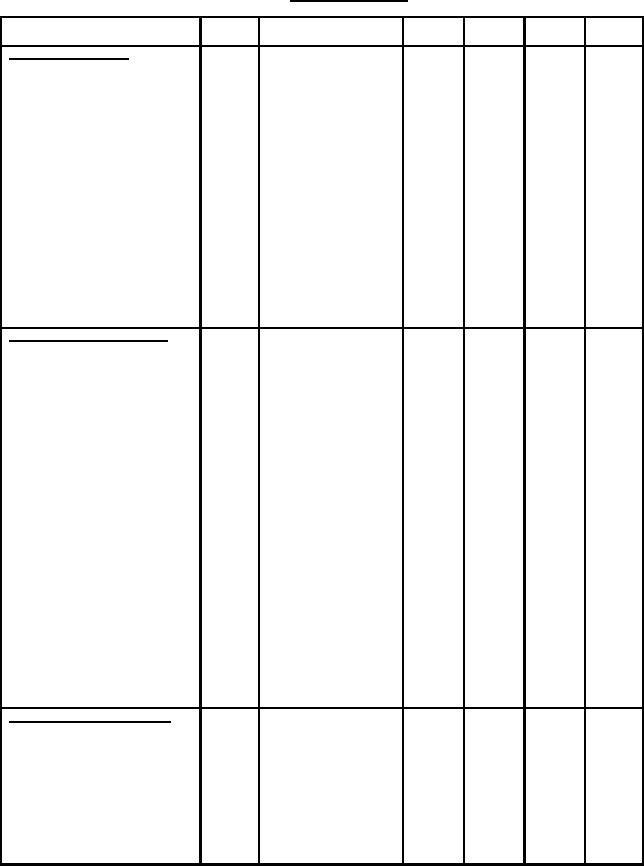

TABLE 1. Testing and Inspection.

Inspection

Method

Conditions

Symbol

Limits

Limits

Unit

Min

Max

Qualification inspection

---

---

---

---

Zone 5 (minimum)

1216

Base material insulating quality

---

---

---

---

1141

Pressure (implosion)

1.0

mm

---

Width

5111

Vibration

11.0

pF

---

Cg1

1331

Direct interelectrode

g1 to all

4.0

pF

---

C1D2

D1 to D2

capacitance

4.0

pF

---

C3D4

D3 to D4

15.0

pF

---

CD1

D1 to all except D2

11.0

---

pF

CD2

D2 to all except D1

10.0

---

pF

CD3

D3 to all except D4

---

11.0

pF

CD4

D4 to all except D3

---

1.63

inch

Dia

5101

Neck and bulb alignment

(electrostatic types)

---

---

---

---

5248

Deflection-factor uniformity

Conformance inspection, part1

---

---

---

---

5106

Bulb, screen and faceplate quality

---

---

---

---

5201

Voltage breakdown

---

---

---

---

5201

Voltage breakdown

(electrostatic types)

---

---

Light = 4 fL note 2

---

---

5206

Gas "cross"

Light

fL

See note 2

---

4.0

5221

Light output

ĆEc1

Light = 4 fL

V dc

48

5223

---

Modulation

mm

5231

15.0

---

Spot position (electrostatic

---

deflection)

mm

5231

7.0

---

Spot displacement (leakage)

Displ

V dc

-67.5

5241

---

Grid cutoff voltage

Ec1

---

---

5251

---

Grid No. 1 leakage current

---

---

5251

---

---

Anode No. 1 leakage current

---

---

---

5251

---

Anode No. 2 leakage current

---

Conformance inspection, part 2

---

---

---

---

1101

Secureness of base, cap or insert

---

---

---

---

1111

Base pin solder depth

mA

660

540

If

1301

Heater current

µA dc

10

-15

Ib1

5201

Ec1 = 0

Electrode current (anode No. 1)

µA dc

1,000

---

Ik

5201

Light = 4 fL

Electrode current (cathode)

See notes at end of table I.

2