MIL-PRF-1/28H

Table 1. Testing and Inspection -Continued.

Inspection

Method

Conditions

Symbol

Limits

Limits

Units

Min

Max

Quality conformance

inspection, part 3

Life-test provisions

---

Group C; t = 500 hours (see note 4)

---

---

---

---

Life-test end points

---

Anode current (see notes 10 and 18)

---

---

---

---

NOTES:

1/ Overall anode to cathode dc supply voltage.

2/ Anode to 9th dynode dc voltage.

3/ An anode load resistance of at least 10,000 ohms is recommended for a protective resistance.

4/ Ebb = 1,000 V adjust luminous flux at cathode initially to obtain Ib = 0.1 mA dc. Color temperature

shall be greater than 2,000 K.

5/ Capacitance between anode and dy9, all other elements grounded.

6/ Capacitance between anode and all other elements.

7/ Test circuit and test equipment requirements:

A bleeder network to provide equal voltage per stage; 8-megohm series resistance for cathode, and all

dynodes excluding the last dynode (9th); 1-megohm series resistance for last dynode (9th) and anode; a

regulated (0.1 percent) power supply with low ripple (0.05 volts peck-to-peck maximum) as a voltage

source; a sensitive dc microammeter to determine anode current; an oscilloscope, with a low-capacity

divider, is connected across the anode load resistance (1 megohm) to monitor noise and breakdown;

base pins of photomultiplier under test connected so that the degradation of breakdown characteristics

is minimized; a vacuum pump, low-pressure chamber and manometer; a light source with an adjustable

iris and sandblasted glass. Mask tube with lightproof material. The light source should be located so that

light from it is striking the cathode of the photomultiplier. (Light from the light source should be the only

light striking the cathode.) The opening of the iris is varied to obtain approximately 10 microamperes of

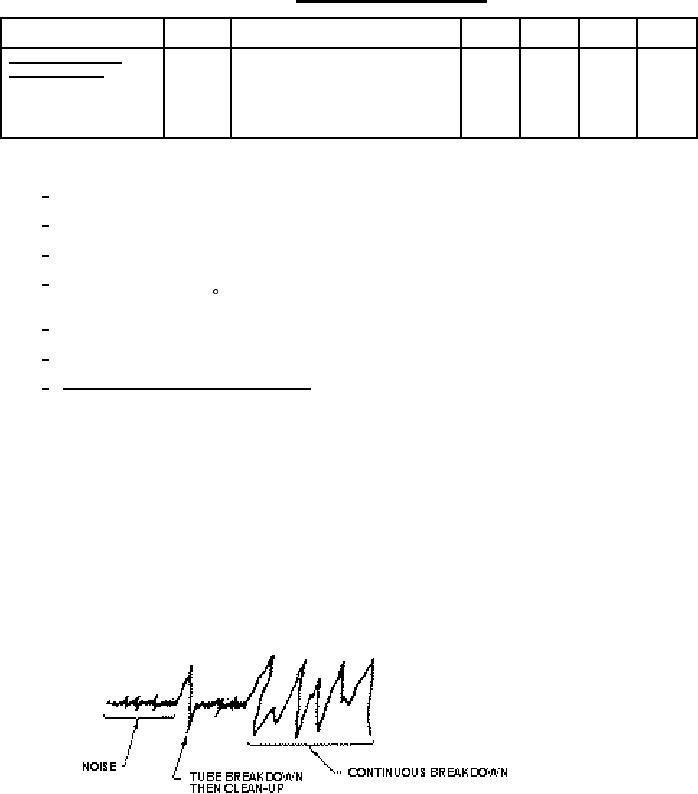

anode current. Observe the tube noise signal as displayed by the oscilloscope. Reduce pressure of vacuum

chamber to 130 mmHg. The tube should be subjected to this pressure for a period of 2 minutes. During

pressure reduction, the tube noise signal, as displayed by the oscilloscope, should be observed to

determine tube breakdown. When breakdown occurs, the signal being monitored by the oscilloscope will

resemble the following:

When continuous breakdown occurs, a change in anode current will result.

3