MIL-PRF-1/28H

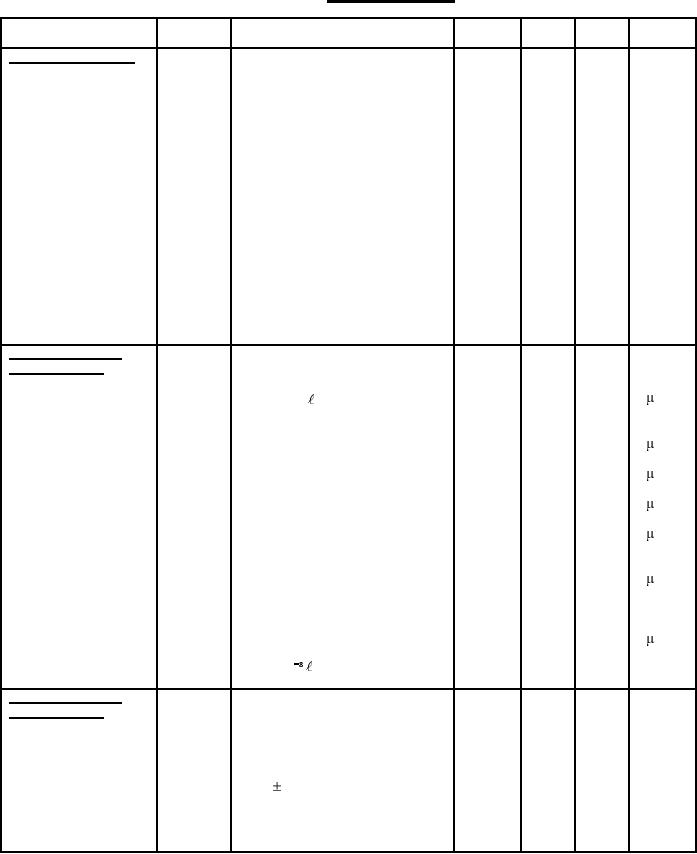

Table 1. Testing and Inspection.

Inspection

Method

Conditions

Symbol

Limits

Limits

Units

Min

Max

Qualification inspection

---

---

---

---

No voltages; t = 60 minutes

1031

Low-frequency vibration

pF

6.0

2.0

C

See note 5

1331

Direct-interelectrode

capacitance

pF

9.5

3.5

C

See note 6

1331

Direct-interelectrode

capacitance

---

---

---

---

Ebb = 1,250 V dc;

---

Low-pressure breakdown

Eb to Edy9 = 125 V dc;

voltages for all other stages = 125 V

dc per stage;

Rp = 1 Meg (see note 7, 8 and 9)

Spectral response

---

---

---

---

S4

identification

5303

Plastic base material

---

---

---

---

See note 13

---

Quality conformance

inspection, part 1

Ik

0.20

---

Cathode current

---

A dc

Light = 0.01 m (see notes 10, 11,

12 and 19)

Ib

400

---

Anode current

5301

A dc

See notes 10, 12 and 19

Lik

---

2.5

5301

Dark current

Light = 0 (see note 19)

A dc

Lib

---

0.05

5301

Dark current (1)

Light = 0 (see note 19)

A dc

Lib

---

1.0

5301

Dark current (2)

Light = 0; Ebb = 1,250 V dc

A dc

(see note 19)

Lib

---

0.006

5301

Dark current (3)

Ebb = 500 V dc; Eb to Edy9 = 50

A dc

V dc; Rp = 10,000 ohms

(see note 19)

Lib

---

0.01

5301

Dark current (4)

Light = 0 (see notes 14 and 19)

A dc

S/N

48

---

5306

Signal to noise ratio

Light = 10 m;

dB

Rp = 0.1 Meg (see notes 15 and 19)

Quality conformance

inspection, part 2

---

---

---

See note 16

---

1101

Secureness of base, cap

or insert

---

---

---

---

1041

Shock

200G

10% (see note 17)

---

---

---

---

1111

Base pin solder depth

---

---

---

---

1105

Permanence of marking

2