MIL-PRF-1/1773C

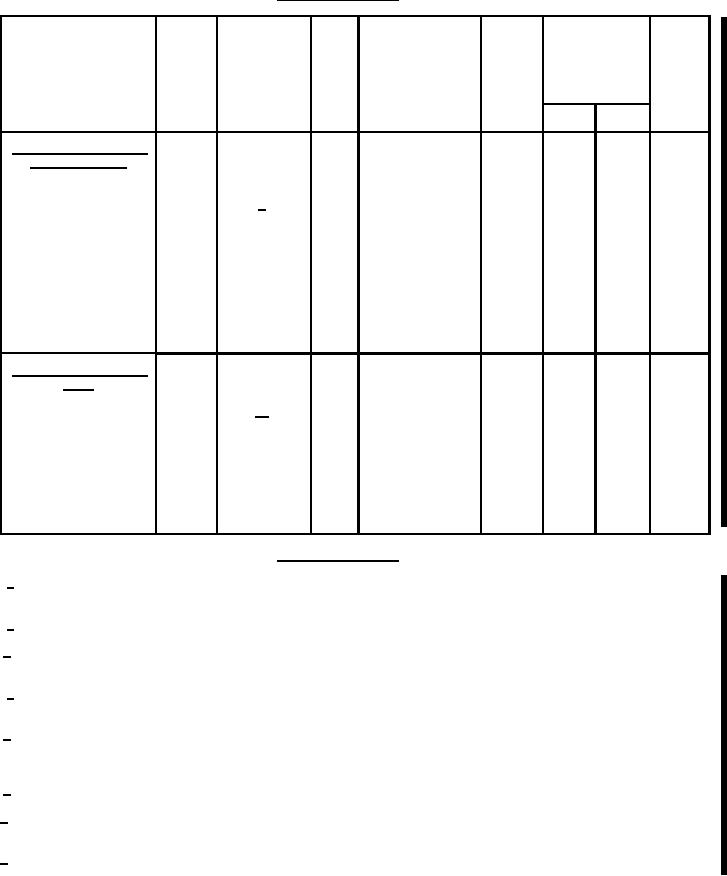

TABLE I. Testing and inspection - Continued.

Limits

Inspection

Method

Notes

Test

Conditions

Symbol

Unit

MIL-

STD-

1311

Min

Max

Conformance inspection,

part 1 - Continued

Pulse stability

1

4315

----

MP

----

0.25

%

6/

3

MP

----

0.25

%

ΔF

----

Frequency pulling

1

4310

----

5

MHz

figure

Note 17 on

Frequency

3

----

Anode T at

F

9,345

9,405

MHz

figures 1

reference point =

thru 4A

+100șC ±10șC

----

Frequency pushing

4311

ΔF/Δib

3

ib = 12 a to 15 a

----

0.1

MHz/a

figure

Conformance inspection,

part 2

10/

Vibration

----

----

Ef = 12.6 V; 15 G;

----

----

----

----

F = 60 Hz; duration

15 minutes; no

heater cathode

shorts during test

Pulse stability

4315

----

3

MP

----

0.5

%

----

5

MP

----

0.25

%

See notes at end of table

TABLE I. Testing and inspection - Continued.

1/

The tube heater shall be protected against arcing by the use of a capacitor that places a minimum capacitance of 4,000 pF

across the heater directly at the input terminals.

2/

A tk of 180 seconds (minimum) with an Ef of 12.6 volts is required before test.

3/

The tube shall be operated into a transmission line with a VSWR of 1.5:1 adjusted in phase to produce maximum spectrum

degradation.

4/

A suitable spectrum shall be considered one in which the major lobe has a shape such that its slope does not change sign

more than once for power levels greater than the specified dB below its peak.

5/

An airflow of 15 cfm at approximately 760 mm Hg shall be directed on the magnetron body from an orifice of 2.5 inches

(63.5 mm) x 1.188 inches (30.18 mm). The temperature rise shall be measured at that point on the anode block as shown

on figure 1 (see figure 1, note 14).

6/

This test shall be the first one performed after 48 holding period.

7/

Air cooling shall be adjusted so that the anode block runs at +150șC, or at the maximum temperature it will reach in the

absence of cooling, whichever is lower. This shall be adjusted during the test condition 3 portions of the cycle.

8/

The tube shall be operated in a transmission line with a load VSWR of 1.5:1 and a variable phase. At specified pressure,

there shall be no evidence of breakdown at the input or output assemblies.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business