MIL-PRF-1/1773C

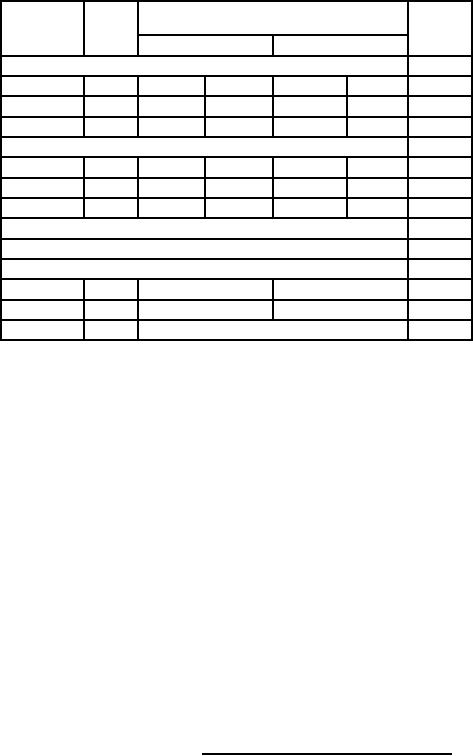

Dimensions

Notes

Figure

Ltr

Inches

Millimeters

Conformance inspection, part 1

Min

Max

Min

Max

4

BS

1.334

1.438

33.88

36.53

4, 4A

BL

.276

.286

7.01

7.26

Conformance inspection, part 3

4

BP

----

2.875

----

73.02

4

BQ

----

.625

----

15.88

4, 4A

BR

.031R

----

0.79

----

Conformance inspection, part 2

Reference dimensions

Nominal

4, 4A

K

.500

12.70

4, 4A

L

.250

6.35

4

BW

.138-32 UNC-2A

NOTES:

1. If these tests have been previously performed by the tube manufacturer, and if the material, manufacturing process, and test

requirements are the same as when the tests were performed, the subject test(s) need not be performed.

2. All metal surfaces black finished except those designated surface S and surface D. Surfaces S shall be gold, silver, nickel

or bright alloy plated, or brass surfaces, except as specified.

3. Hermetic connections may be made to surface D.

4. Axis of cathode terminal shall occupy specified location within .047 inch (1.19 mm) radius. Note 7 shall apply.

5. Limits include angular and lateral deviations.

6. With diameter AX resting on a plane surface coincident with reference plane A, a gauge .010 inch (0.25 mm) thick and .125

inch (3.18 mm) wide shall not enter, and areas of the base plate outside diameter AX shall be within .010 inch (0.25 mm) of

the plane surface.

7. With diameter Y resting on a plane surface, a gauge .005 inch (0.13 mm) thick and .125 inch (3.18 mm) wide shall not enter.

8. Any portion of the assembly which extends below reference plane A shall be within .625 inch (15.88 mm) radius of specified

axis of input.

9. Defines extremity of cylindrical section designated BG.

10. Defines extremity of cylindrical section designated BJ.

11. Clamping shall be confined to this area.

12. Heater terminal and cathode terminal shall be concentric within .010 inch (0.25 mm).

13. Protective covers shall be provided with tubes.

14. Reference planes A, B, and C are mutually perpendicular.

15. Reference point for cathode temperature measurements. Located on the diameter, dimension BX.

16. Gold, silver, or nickel plate over full extent of maximum plug penetration.

17. Reference point for anode temperature measurements. Located on body near output section.

18. Extremity of magnet lug shall coincide with reference plane C within .094 inch (2.39 mm).

19. For vibration tests, planes of vibration shall be reference planes A, B, and C.

20. See note 21. Warning: Maintain minimum 2.00 inches (50.8 mm) between this magnet and magnetic materials (magnets,

steel tool, and plates).

21. Manufacturers code designation and tube serial number shall appear within this area.

FIGURES 1 THROUGH 4A. Outline drawing of electron tube type DOD-042.

15

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business