MIL-PRF-1/1756B

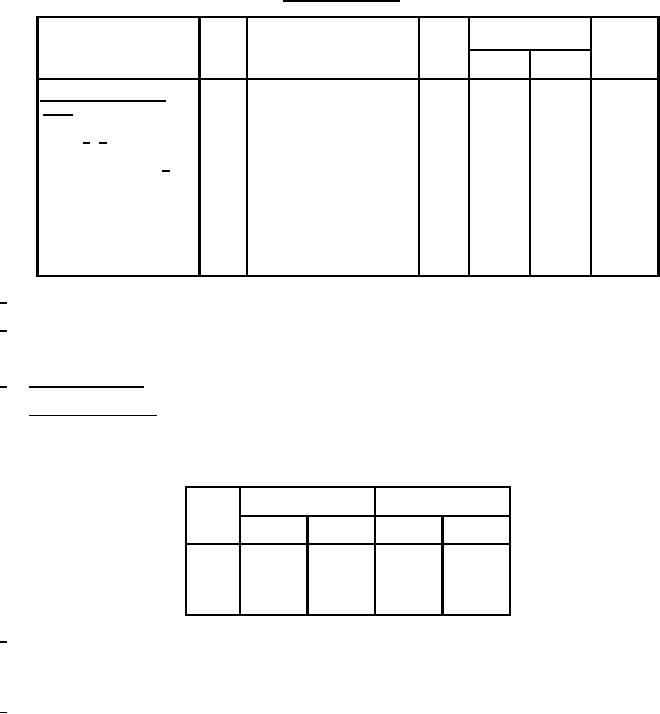

TABLE I. Testing and inspection - Continued.

Conditions

Limits

Unit

Inspection

Method

Symbol

Min

Max

Conformance inspection,

part 3

----

----

----

No voltages

Torque 5/ 7/

----

----

----

----

----

Condition A; no voltages; fixture.

----

Shock, specified pulse 5/

1042

Torque and shock test

----

end point:

µA dc

-10

----

Ic

1266

Total grid current

1/

All test listed under conformance inspection, part 1, shall be performed at the conclusion of the holding period.

2/

The electrode voltage (2) grid test may be performed alternately in the following manner:

Eb = 600 V dc; Ec/Ib = 1.0 mA dc; and the limit for Eco shall be -15.0 V dc (max).

3/

Grid-anode resonance. Test in cavity. Cavity shall resonate at 1,354 ±2.0 MHz with tuning slug at TA = 25ºC ±5ºC.

Grid-cathode resonance. Test in cavity. Cavity shall resonate at 1,719 ±2.0 MHz with tuning slug at TA = 25ºC ±5ºC.

W hen plotted on graphs of resonant frequency versus grid-anode capacitance and resonant frequency versus gird-cathode

capacitance, the tube under test shall be represented by a point within a parallelogram whose four corners are located by the

following points:

Points

Capacitance (pF)

Frequency (MHz)

C-gp

C-gk

F-gp

F-gk

1,730

1,965

6.30

1.85

1

1,780

2,015

6.30

1.85

2

1,690

1,850

7.50

2.15

3

1,740

1,900

7.50

2.15

4

4/ At zero hours, establish the drive conditions necessary to obtain ib = 2.0 a (peak anode current) with Eb = 2,000 V dc and a bias

voltage Ec = -40 V dc. the pulse width (tp) of the modulator shall be 2 µs minimum and the duty (Du) shall be 0.0025 maximum.

W ith the drive level determined at zero hours, check the anode current at end of life. The maximum allowable drop in anode current

(Ćib) shall be 25 percent.

5/ This test will be performed quarterly, with 8 samples. Acceptance shall be based upon accept on zero failures. All tests shall be

considered as nondestructive except in case of failure, and separate samples may be used for each test at the option of the

manufacturer. In case if failure, the failing test shall become a conformance inspection, part 2, acceptance on zero failures, for three

consecutive successful submissions, at which time the testing may revert to the conformance inspection, part 3 basis.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business