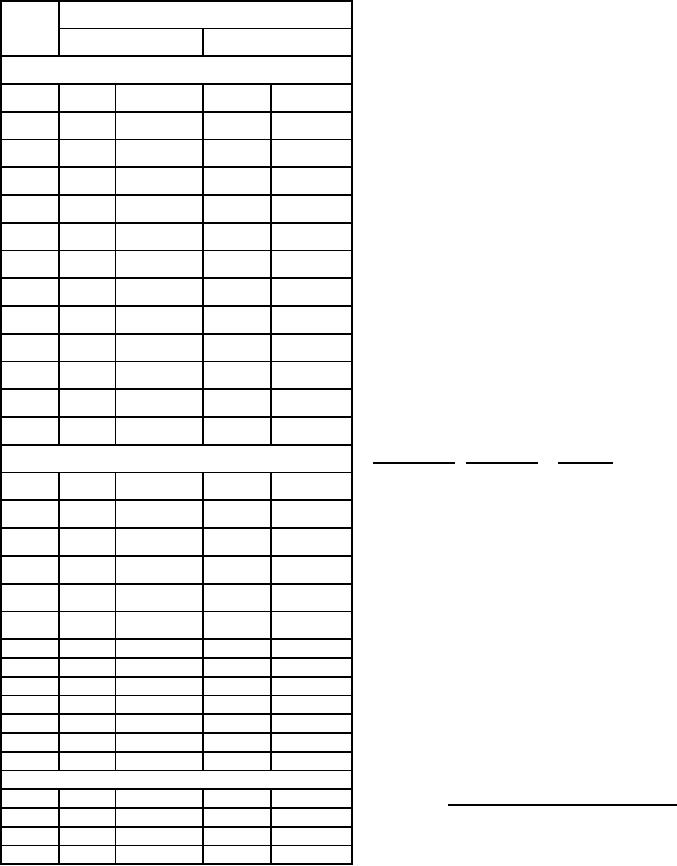

MIL-PRF-1/1726B

Dimensions

NOTES:

LTR

1. Insulation material is required between heater and

Inches

Millimeters

heater-cathode and shall be securely affixed.

2. Dimensions shall be checked during the the initial production

Conformance inspection, part 2

and once each succeeding 12-calendar months in which there

is production. A regular double sampling plan shall be used,

Min

Max

Min

Max

with the first sample of three tubes with an acceptance number

of zero, and a second sample of three tubes with a combined

A

1.815

1.875

46.10

47.63

acceptance number of one. In the event of failure, the test shall

be made as a part of conformance inspection, part, 2, code

B

---

1.534

---

38.96

level D, with an acceptance level of 6.5. The regular "12-

calendar month" double sampling plan shall be reinstated after

C

---

1.475

---

37.47

three consecutive samples have been accepted.

3. Silver plated 30 MSI minimum.

D

1.289

1.329

32.74

33.76

4. Plating not required over radiator and radiator support

of copper, aluminum, or approved equivalent.

F

.970

1.010

24.64

25.65

5. This surface shall be used for measurement of anode

shank temperature.

G

.462

.477

11.73

12.12

6. Holes for tube extractor through top fin only.

J

.766

.826

19.46

20.98

7. Inner edge of heater and outer edge of cathode rf

connection shall be free from burrs and sharp edges.

N

1.025

1.035

26.04

26.29

8. This fin shall withstand a 6-inch drop test without

loosening and without distortion as judged by ability

R

.655

.665

16.64

16.89

to maintain dimension K. Note 2 shall apply.

9. Distortion of fins permissible provided distance between

T

.213

.223

5.41

5.66

adjacent fins at any point on circumference meets

tolerances for dimension K.

U

.315

.325

8.00

8.26

10. Eccentricity of contact surfaces shall be gauged from

center line of reference and shall be as follows.

Z

1.120

1.130

28.45

28.70

Note 2 shall apply.

Conformance inspection, part 3 (see note 2)

Reference

Contact surface TIR maximum

E

.125

.185

3.18

4.70

Anode

.020

Cathode

Grid

.020

Cathode

H

---

.040

---

1.02

Heater

.012

Cathode

K

.025

.046

0.64

1.17

11. Diameters N, R, T, and U shall apply throughout

entire contact areas as defined by dimensions

L

1.234

1.264

31.34

32.11

AA, AB, AC, and AD, respectively.

12. Dimensions in electrode contact areas table are for

M

1.180

1.195

29.97

30.35

socket design purposes and are not intended for

inspection purposes.

P

.772

.792

19.61

20.12

13. This surface shall not be used for clamping or locating.

Q

.650

.850

16.51

21.59

S

---

.545

---

13.84

V

---

.086

---

2.18

W

---

.100 RAD

---

2.54 RAD

AE

.420

---

10.67

---

AF

.105

.145

2.67

3.68

AG

---

.035 RAD

---

0.89 RAD

Electrode contact areas - see note 12)

AA

.035

.361

0.89

9.17

FIGURE 1. Outline drawing of electron tube type 8533W -

Continued.

AB

1.185

1.265

30.10

32.13

AC

1.534

1.728

38.96

43.89

AD

1.475

1.815

37.47

46.10

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business