MIL-PRF-1/1726B

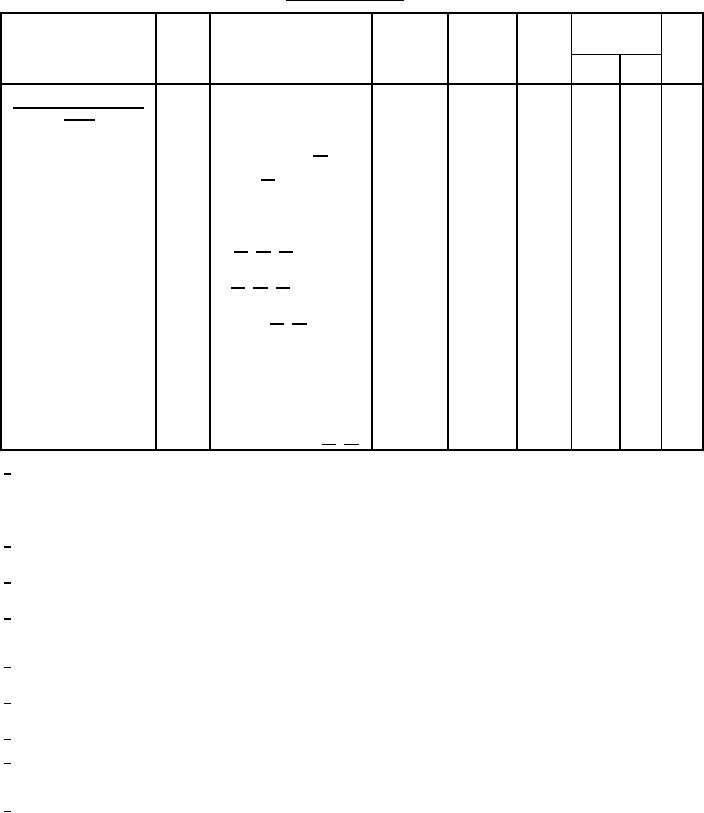

TABLE I. Testing and inspection - Continued.

Inspection

Limits

Inspection

Method

Conditions

Acceptance

level or

Symbol

Unit

level

code

Min

Max

Conformance inspection,

part 3

Life test

---

Group C; filament standby;

---

---

---

---

---

---

t = 500 hours

18/

'ib

Life-test end point

---

18/

---

---

---

25

%

Variable-frequency

---

F = 55 to 500 Hz; accel

---

---

---

250

mV ac

Ep

vibration

= 10 G (peak); Ebb = 400

V dc; Rp = 10,000 ohms;

Ec/Ib = 10 mA dc

10/ 13/ 14/

Torque

---

No voltages applied

---

---

---

---

---

---

10/ 13/ 15/

Shock

1042

Condition A; no voltages

---

---

---

---

---

---

applied

13/ 16/

Torque and shock-test

---

end point:

---

---

---

-10

Ic

A dc

Total grid current

1266

Barometric pressure,

1002

Pressure = 35 mmHg (max);

---

---

---

---

---

---

reduced

voltage = 1,800 V ac;

TA = +30qC r10qC 13/ 17/

1/

The transit-time heating effect of the cathode may require compensation by a reduction in heater voltage after dynamic operation

of the tube has started. The back heating is a function of frequency, grid current, grid bias, anode current, duty cycle, and circuit

design and adjustment. There is an optimum heater voltage which will maintain the cathode at the correct operating temperature

for a particular set of operating conditions. A maximum variation of r5 percent from optimum is permitted. No reduction in heater

voltage is required up to and including 500 MHz.

2/

The regulation or series-anode-supply impedance, or both, shall limit the instantaneous peak current, with the tube considered as

a short circuit, to a maximum of 10 times the specified maximum current rating.

3/

The maximum instantaneous peak grid voltage CW ratings shall be within the range of +30 to -400 volts. The maximum

instantaneous peak grid voltage for grid-pulse conditions shall be within the range +250 to -750 volts.

4/

Sufficient conduction, convection, and forced-air cooling shall be provided to limit the envelope and anode shank temperatures to

the specified value under all operating conditions. Reliability will be seriously impaired if the maximum is exceeded. Where

emphasis is placed on long and reliable life, lower temperatures should be used.

Unless otherwise specified, at an anode dissipation of 100 watts and with an incoming air temperature of 25qC maximum at sea

5/

level, a minimum airflow of 12.5 cfm shall be directed across the anode cooler, using the cowl as shown on Drawing 157-JAN.

6/

Sufficient conduction, convection, and forced-air cooling may be used in all electrical tests involving application of heater voltage

to maintain the anode shank and seal temperatures within the specified maximum value.

7/

This test is to be the first test performed at the conclusion of the holding period.

8/

After heater warmup, the anode voltage shall be raised slowly to 10 kV dc. Intermittent arcing may occur as the anode voltage is

increased, but more than 5 arcs shall be cause for rejection. The voltage shall be held at the 10 kV dc level for 60 seconds; if any

arcs occur during this time, or Ib exceeds the specified limit of 1.0 mA dc, the tube shall be rejected.

9/

Airflow through the anode radiator shall be between 3.5 and 4.0 cfm with the cowl as shown on Drawing 157-JAN. The grid

current shall be measured not less than 5 minutes after the anode dissipation has been set at 100 watts.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business