MIL-PRF-1/1716B

TABLE I. Testing and inspection - Continued.

1/

Minimum airflow requirements for incoming air at 50°C maximum at sea level are shown in table I. In all cases of operation a

socket that provides for forced-air cooling of the base shall be used and maximum temperature ratings shall not be exceeded.

Ratings apply for bias voltage of less than -500 volts and frequencies less than 110 MHz. Air cooling of the tube base shall be

increased with higher values of bias or frequency. The approximate pressure drop values shown include the EIMAC SK-300A air-

system socket or equivalent, with an EIMAC SK-1306 chimney, or equivalent, with air passing in a base-to-anode direction. Airflow

shall be applied before or simultaneously with the application of electrode voltages (including the filament), and should normally be

maintained for a brief period after all voltages are removed to allow for tube cool-down. In cases where long life and consistent

performance are factors, cooling in excess of minimum requirements is normally beneficial.

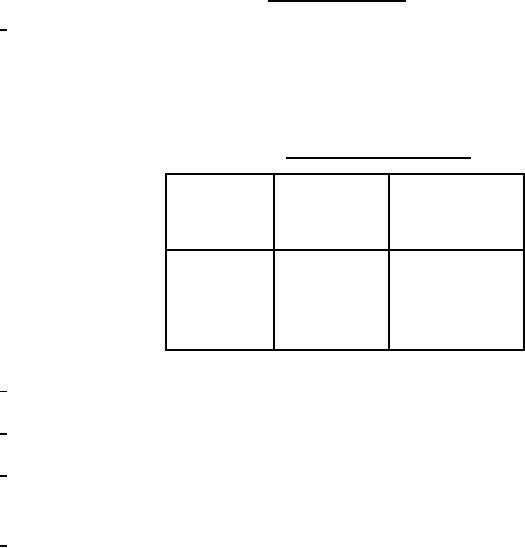

TABLE IA. Minimum airflow requirements.

Anode dissipation

Airflow

Approximate

(watts)

(cfm)

pressure

drop (In.H20)

0.4

110

4,000

0.8

200

6,000

1.7

315

8,000

2.8

445

10,000

4.4

600

12,000

2/

Any change in filament current resulting from the vibration or shock testing (considered individually) shall not exceed the specified

limit for ĆIf.

3/

In all electrical tests involving application of filament voltage, it is permissible to use an air-system socket and chimney, and forced-

air cooling is permitted.

4/

The tube manufacturer warrants the tube for one year from the date of shipment, or 1,000 hours of filament life, whichever first

elapses. This warranty applies only when the tube is operated within the maximum ratings (see "Absolute ratings" of MIL-PRF-1).

A defective tube shall either be replaced or at the option of the manufacturer a credit shall be made in the amount of the original

purchase price prorated on the basis of 1,000 hours of "filament-on" time.

5/

This specification sheet uses accept on zero defect sampling plan in accordance with MIL-PRF-1, table III.

4