MIL-PRF-1/1688C

OUTLINE DIMENSIONS SIMILAR TO 242-JAN (REF)

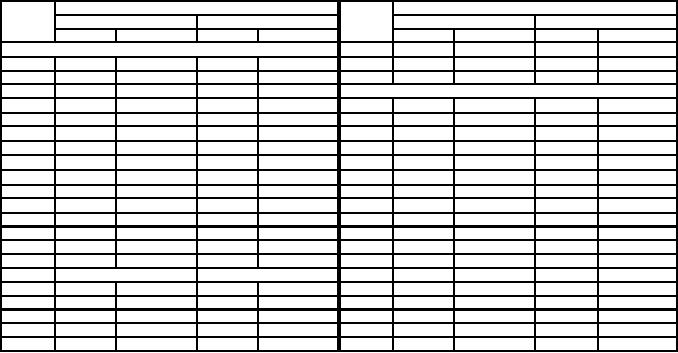

Dimensions

Dimensions

Ltr

Inches

Millimeters

Ltr

Inches

Millimeters

Min

Max

Min

Max

Min

Max

Min

Max

1130'

1630'

1130'

1630'

Conformance inspection, part 1

AU

E

---

2.156 Nom

---

54.76 Nom

AV

---

.313 Nom

---

7.95 Nom

F

---

1.359 Nom

---

34.52 Nom

AW

---

2.812 Nom

---

71.42 Nom

L

---

1.437 Nom

---

36.50 Nom

Conformance inspection, part 2

2948'

3012'

2948'

3012'

N

1.417

1.457

36.00

37.01

A

R

---

1.440 Nom

---

36.58 Nom

B

.205

.215

5.21

5.46

4448'

4512'

4448'

4512'

T

---

3.500 Nom

---

88.90 Nom

C

2948'

3012'

2948'

3012'

X

---

1.437 Nom

---

36.50 Nom

D

2948'

3012'

2948'

3012'

Z

---

.756 Nom

---

19.20 Nom

G

4448'

4512'

4448'

4512'

AC

2.287

2.307

58.09

58.60

H

AD

2.060

2.110

52.32

53.59

J

2.266 R

2.296R

57.56 R

58.32 R

2948'

3012'

2948'

3012'

AE

1.125

---

28.57

---

K

AF

2.314

2.328

58.77

56.84

M

2.029 R

2.035 R

51.54 R

51.69 R

AG

.550

.560

13.97

14.22

P

.500

---

12.70

---

AH

1.420

1.460

36.07

37.08

S

1.063

---

27.00

---

AJ

---

1.620

---

41.15

U

---

2.656R

---

67.46 R

30

35

30

35

AL

2 1/2-18 NS-2A

2 1/2-18 NS-2A

V

AN

---

.187 Nom

---

4.75 Nom

W

1.500 R

---

38.10 R

---

AP

.438

.688

11.12

17.47

Y

1.500

---

38.10

---

AR

.525

.625

13.33

15.87

AB

.803

.833

20.40

21.16

AS

---

.025 Nom

---

0.64 Nom

AK

.593

---

15.06

---

AT

---

1.740

---

44.20

AM

6.219

6.407

157.96

162.74

NOTES: (MECHANICAL REQUIREMENTS)

1. The periphery of the anode shall lie within a 2.160 inch (54.86 mm) diameter circle located as specified for non-tunable side

of anode.

2. Maximum width specified applies to area defined by broken line and circumference of radiator.

3. Center-line of maximum diameter shall be concentric with center-line of guard pipe to within 0.040 inch (1.02 mm).

4. Applies to inner conductor insert only center-line of inner conductor insert shall be concentric with center of guard pipe to

within 0.025 inch (0.64 mm).

5. Applies to straight portion of inner conductor wall.

6. No sharp edges of outside diameter at end of inner conductor.

7. Tube may be supported by plate (mounting) or guard pipe.

8. Spline for adjusting tuning mechanism is as follows: 12 teeth 48 pitch - 0.250 inch (6.35 mm) pitch diameter.

9. This annular area shall be flat within 0.015 inch (0.38 mm) (a thickness gauge 0.125 inch (3.18 mm) wide shall not enter

more than 0.250 inch (6.35 mm).

10. Pyrex glass or approved equivalent.

11. Leads shall be flexible and slack.

12. Tuning mechanism will provide full range of tuning with five 360 turns, maximum.

13. Protective guard for shipping purposes.

14. The center of the jack holes shall be within a radius of 0.100 inch (2.54 mm) of the location specified but shall be spaced

0.797 inch (20.24 mm) 0.015 inch (0.38 mm) with respect to each other.

15.

Common cathode connection marked with letter "C":

Hex locking head banana pin jack 0.594 inch (15.09 mm) long, hole 0.169 inch (4.29 mm) 0.005 inch (0.13 mm).

16.

17. Paint with heat-resistant non-corrosive paint; the following shall be free from paint-top surface of mounting plate parts above

mounting plate, screw threads on guard pipe and all surfaces inside guard pipe, tuning gear, stop assembly, and worm shaft

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business