MIL-PRF-1/1677B

TABLE I. Testing and inspection - Continued.

14/

This test is to be performed after the holding period.

15/

The mode discontinuity percentage shall be defined as the ratio of the power level at which a discontinuity in the mode shape

is exhibited to the maximum power level.

16/

Apply 300 V dc between the elements specified. The resulting current shall not exceed the limits specified. No other

voltages are to be applied.

17/

With a 1.5 to 1 voltage standing wave inserted in the guide, there shall be no discontinuity at the maximum power points for

any phase of standing wave.

18/

The change in reflector voltage required to tune across the specified minimum electrode tuning range (not to 1/2 power

points) shall not exceed the limit specified. The center of the electronic tuning range is to be the maximum power point of the

mode.

19/

Modulation sensitivity is defined as the specified electronic tuning range (50 MHz) divided by the reflector voltage between

the ±25 MHz points.

20/

Mechanical tuning range: The total number of turns of the tuner shaft between mechanical stops shall be 6 to 9 turns. The

midpoint of the total tuner shaft travel shall be the reference point for measurement of the tuning range. The specified tuning

range of 15.8 to 16.2 GHz shall be covered in any portion of the travel of the tuning shaft within ±2 turns of the reference point

as limited by the tuner shaft sensitivity (1) requirement.

Tubes shall operate at an ambient temperature of 25°C to 40°C with no cooling except convection and conduction to the

21/

waveguide (UG-419).

22/

With reflector voltage set at the specified value, the power output shall be within the amount specified of the power output

obtainable by optimizing the reflector voltage at the frequency specified.

23/

Preproduction sample approval requirements hereby replace any qualification requirements referable to the product covered

herein. The term "First Article Testing" shall be considered synonymous with the term "Preproduction Sample Approval

Testing." All tests applicable herein (including all preproduction sample approval and conformance inspection, parts

1, 2, and 3) shall be performed during preproduction sample inspection. A failure of any one tube in any of the tests shall be

cause for preproduction sample disapproval.

24/

Wire shall be MIL-DTL-16878/7, type F-22.

25/

Connector plug shall be Continental type No. C7-20P-V SC4HC or Amphenol type 126-195.

26/

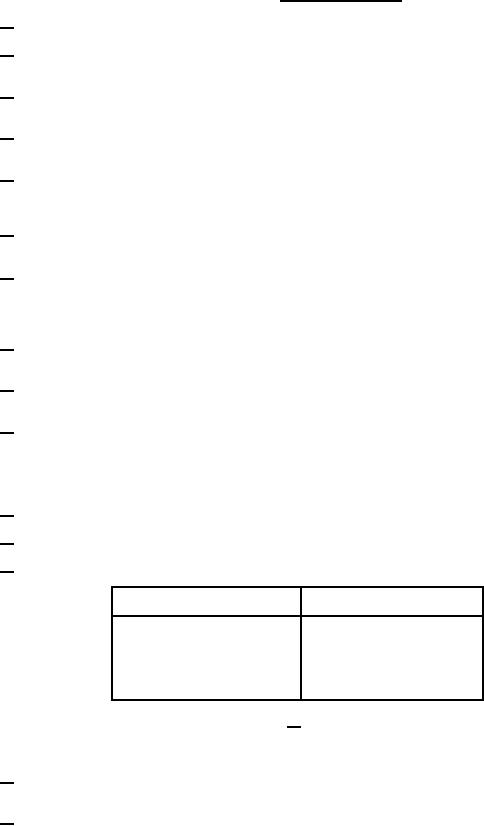

Plug connections shall be as follows:

Pin

Element

connection

Cathode

A

Heater

C

Reflector

D

Heater

E

Shell

H

NOTE: Wire size described in 24/

All testing of the tube to be done only after assembly of plug to the tube.

27/

The acceptance level for the combined defectives for attributes in acceptance inspection, part 1, production, excluding

mechanical and in-operatives, shall be 1.0 percent.

28/

All tests on this specification shall be performed at the conclusion of the specified non-operating holding period commencing

with the total reflector current test.

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business