MIL-PRF-1/1664B(NAVY)

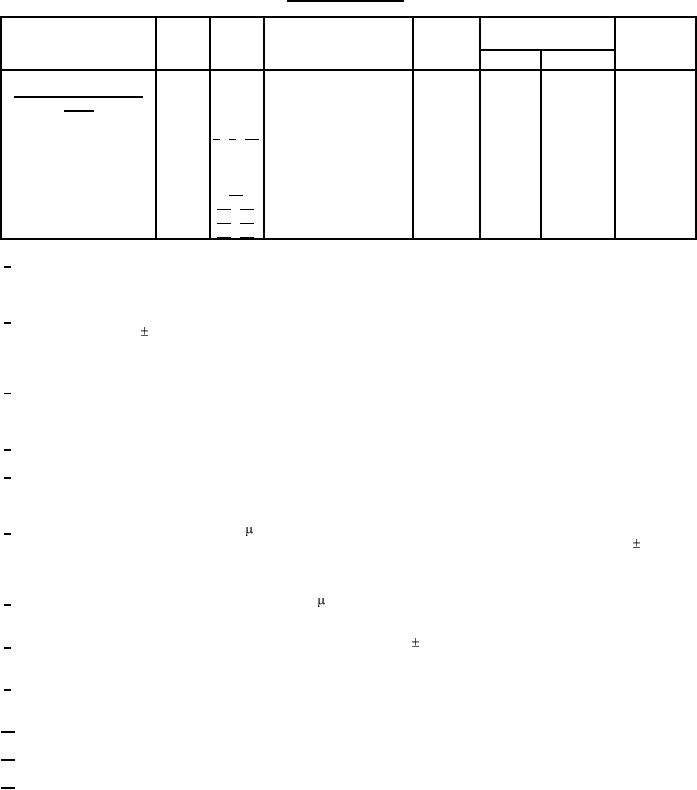

TABLE I. Testing and inspection - Continued.

Inspection

Method

Notes

Conditions

Symbol

Limits

Unit

Min

Max

Conformance inspection,

part 3

Life test

1/ 5/ 26/ Group D

t

1,500

----

Hours

Life test end points:

Power output

4250

13/

Po

40

----

kW

RF bandwidth

4308

13/ 21/

BW

----

2.5/tpc

MHz

Minor lobe ratio

4308

13/ 21/

Ratio

6

----

dB

Stability

4315

13/ 17/

MP

----

0.5

%

1/

Cycle life tests of 30 minutes "on" preceded by 3 minutes maximum filament schedule and 7 minutes "off" shall be required until

the total accumulated "on" time equals the specified life. During the "on" periods, a VSWR of 1.5:1 maximum shall be introduced

into external load circuit and the phase adjusted through 22 G during each "on" time.

2/

Prior to the application of high voltage, the cathode shall be heated to the required initial operating temperature. This may be done

by applying 4.0 volts 5 percent for 3 minutes. On the application of anode power, the heater voltage should be lowered to the

voltage specified. The tube heater shall be protected against arcing by the use of a connector that places a minimum capacitance

of 4,000 pF across the heater directly at the input terminals.

3/

To relate the various parameters, use the following formula:

Pi = ib x Du x 16,000

4/

Heater voltage shall be 2.7 V for 0.0007 duty cycle.

5/

The characteristics of the applied pulse must be those which result in proper starting and oscillation. The rate of pulse voltage

rise, the percentage of pulse voltage ripple, and the rate of pulse voltage fall are among the more important considerations. The

cognizant service electron tube group should be consulted regarding pulse characteristics as related to the specific application.

6/

The rrv shall be expressed in kv for each s defined by the steepest tangent to the leading edge of the voltage pulse about 80

percent amplitude. Any capacitance used in viewing system shall not exceed 6.0 pF. No spike or ripple shall exceed 7 percent

of the average peak value of voltage or current. Inverse voltage shall not exceed 20 percent of the forward voltage. The negative

amplitude of any post pulse voltage oscillation shall not exceed 10 percent of the average peak value.

7/

The rate of rise of voltage (rrv) shall be expressed in kv/ s defined by the steepest tangent to the leading edge of the voltage pulse

above 50 percent amplitude. Any capacitance used in viewing shall not exceed 6.0 pF.

8/

The mounting plate shall provide for cathode terminal pressurization of 25

2 psia and a leak rate not to exceed 0.1 standard cubic

inch for each minute.

9/

With the specified cooling arrangements and conditions, the anode and input bushing temperatures shall not exceed the specified

values.

10/

Unless otherwise specified, a total airflow of approximately 20 cfm shall be used for cooling.

11/

The temperature is to be measured at the points indicated on figure 1.

12/

In handling and mounting the magnetron, care shall be exercised to prevent demagnetization. A minimum distance of 6 inches

shall be maintained between the tube and ferromagnetic materials or energized magnets.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business