MIL-PRF-1/1661C

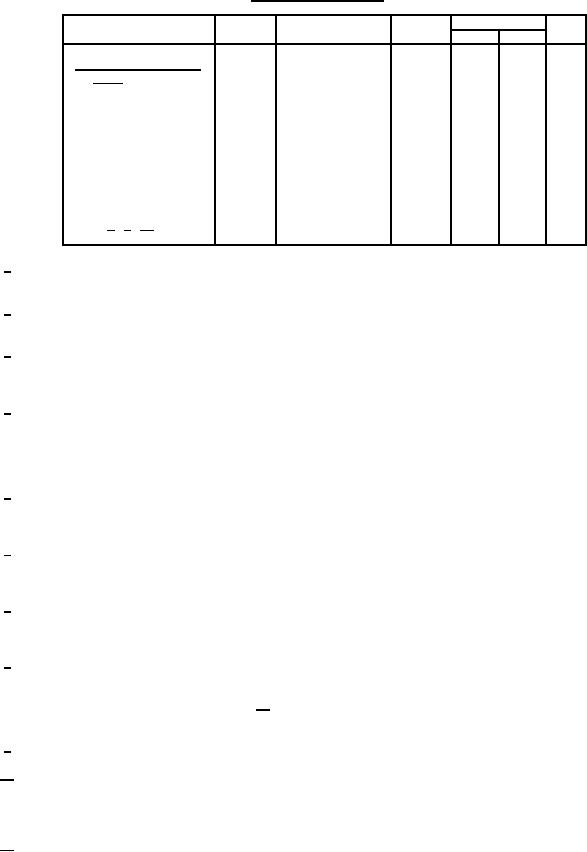

TABLE I. Testing and inspection - Continued.

Limits

Inspection

Method

Conditions

Symbol

Min

Max

Unit

Conformance inspection,

part 3 - Continued

Shock and variable-

frequency vibration

end points:

----

----

----

----

3246

Operation (1)

0.005

----

tj

3261

Time jitter

µs

Operation at elevated

3246

egy

----

150

v

TA = 150°C;

ambient temperature

t = 5 hours

5/ 8/ 10/

1/

Instantaneous starting is permissible. The maximum permissible epy is 8.0 kv and shall not be attained in less

than 0.04 seconds.

2/

In pulsed operation, the peak inverse voltage, exclusive of a spike of 0.05 µs maximum duration, shall not exceed 2.0

kv during the first 25 µs following the anode pulse.

3/

The driver pulse, measured at the tube socket with thyratron grid disconnected shall have the following

characteristics: 175 volts minimum; 600 volts maximum; tr = 0.35 µs maximum; grid pulse duration 2.0 µs minimum.

Impedance of drive circuit: 50 to 1,500 ohms. At -55°C, a minimum of 250 V is required.

4/

This shall be the first test after the holding period. The tube shall operate satisfactorily on push-button starting within

three attempts when the anode voltage (epy) is applied to the tube under test in such a manner as to rise from 0 to 8

kv minimum within 0.03 second. (The filter in the rectifier shall be so designed that the epy reaches at least 4 kv

within 0.015 second). The interval between successive attempts to instantaneously start the tube shall be not less

than 10 nor more than 30 seconds. Any tube failing to start within three attempts shall be considered a failure.

5/

The circuit constants shall be so chosen, that at epy = 14 kv under resonant charging conditions; dik/dt = 1,500 a/µs

(min); ib = 150a (min); tp = 1.0 µs ± 10 percent; prr = 1,000 pps (min); Rg1 = 30,000 ohms. Grid pulse

characteristics shall be: tp = 2.0 µs (max); tr = 0.34 µs (min); and driver impedance = 500 ohms (min).

6/

This test shall be performed simultaneously with the operation (1) test. An anode delay time measurement shall be

made at the end of 2 and 10 minutes of the operation (1) test. The change in anode delay time (with respect to the

2 minute reading) shall not exceed the specified value.

7/

The tube shall be tested by applying a peak forward anode voltage not to exceed the value specified in the test

conditions for the time jitter test immediately after the cathode warmup period (tk). After 60 seconds of operation the

variation in firing time (tj) shall be not greater than the amount specified.

8/

This test shall be performed during the initial production and once each succeeding 12-calendar months in which

there is production. An accept on zero defect sampling plan shall be used, with sample of three tubes with an

acceptance number of zero defects. In the event of failure, the test will be made as a part of conformance inspection,

part 2, with an acceptance level of 6.5 (see 11/). The regular "12-calendar month" sampling plan shall be reinstated

after three consecutive samples have been accepted.

9/

There shall be no pronounced resonance in the range from 0 to 2,000 Hz.

10/

This test shall be conducted for a total of 5 consecutive hours with no more than 3 kickouts and with no evidence of

detrimental anode heating. The tube shall be started with 107.5 percent Ef and operate at this value for 4 hours. At

the start of the fifth hour, and while the tube is still operating, the voltage shall be lowered to Ef = 92.5 percent and

remain there for the final hour of operation.

11/

This specification sheet uses accept on zero defect sampling plan in accordance with MIL-PRF-1, table III.

3