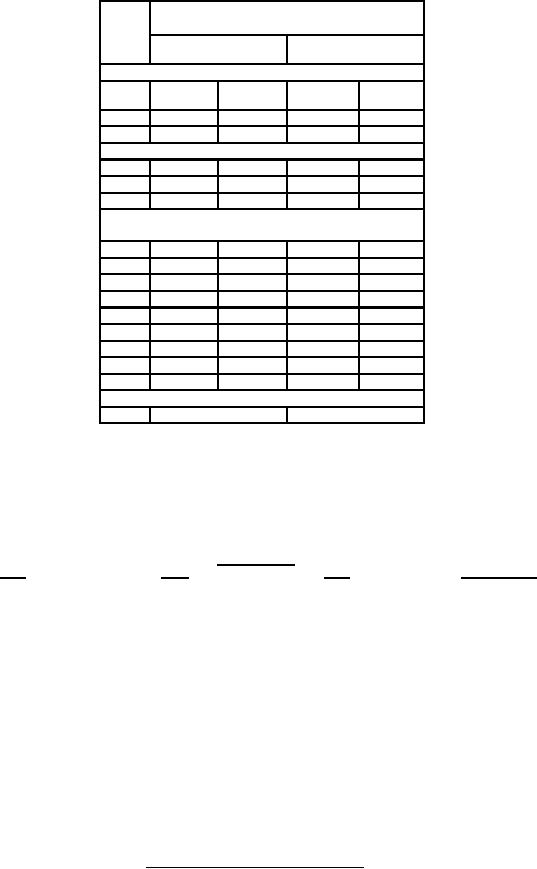

MIL-PRF-1/1658C

Dimensions (see note b)

Ltr

Millimeters

Inches

Conformance inspection, part 1

Min

Max

Min

Max

A

428.63

479.43

16.875

18.875

B

----

142.88

----

5.625

Conformance inspection, part 2

D

304.80

330.20

12.000

13.000

E

214.12

217.42

8.430

8.560

G

96.60

97.10

3.803

3.823

Conformance inspection, part 3 (see note i)

(see notes c, e, f, g, and h)

C

----

76.20

----

3.000

F

----

160.32

----

6.312

J

95.25

146.05

3.750

5.750

L

111.13

117.48

4.375

4.625

M

----

285.75

----

11.250

N

15.24

16.51

0.600

0.650

P

25.40

50.80

1.000

2.000

Q

22.23

47.63

0.875

1.875

R

7.85

8.00

0.309

0.315

Nominal dimensions (see note a)

H

3.18

0.125

NOTES:

1. Dimensions without tolerances are for information only and are not required for inspection purposes.

2. Metric equivalents (to the nearest 0.01 mm) are given for general information only and are based upon 1 inch = 25.4 mm.

3. Anode terminal shall be No. 10-32 UNC-2A roundhead machine screw 3/8 inch (9.53 mm) long with washer. The anode terminal

extension may be removed for shipment.

4. Leads shall be flexible. Lead connections shall be suitably identified. Lead connections, lead identification, lead insulation, and

lead insulation sleeving shall be inspected under periodic check and shall be as follows:

Lead insulation

Lead

Color

Type

Sleeving Color

H (heater)

Yellow

HA-1

Yellow

G (grid)

Yellow or Green

HA-1

Green

R (reservoir)

Red

HA-1

Red

5. Lead terminal shall be in accordance with figure 2.

6. Insulation sleeving shall be as specified in MIL-I-3190.

7. Dimensions C and F define extent of rigid portion of tube below mounting flange. Clearance for this part of tube shall be provided

in equipment.

8. Holes R shall be inspected for orientation by using the base gage outlined on figure 3.

9. These dimensions shall be checked during the initial production and once each succeeding 12-calendar months in which there is

production. An accept on zero defect sampling plan shall be used, with a sample of three tubes with an acceptance number of

zero. In the event of failure, the dimension checks shall be made a part of conformance inspection, part 2, code level D, with an

acceptance level of 6.5 (see note 10). The regular "12-calendar months" sampling plan shall be reinstated after three consecutive

samples have been accepted.

10. This specification sheet uses accept on zero defect sampling plan, in accordance with MIL-PRF-1, table III.

FIGURE 1. Outline drawing of electron tube type 8789 - Continued.

8

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business