MIL-PRF-1/1648C(NAVY)

Dimensions

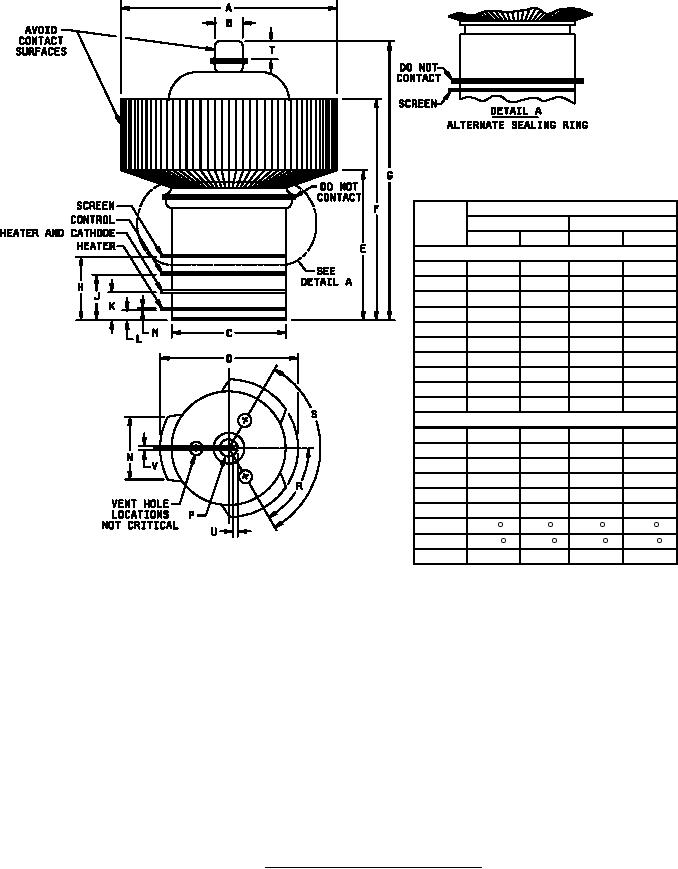

Ltr

Inches

Millimeters

Min

Max

Min

Max

Conformance inspection, part 2

C

1.870

1.900

47.50

48.26

G

4.600

4.800

116.84

121.92

H

.965

.988

24.51

25.10

J

.690

.710

17.53

18.03

K

.415

.435

10.54

11.05

L

.140

.165

3.56

4.19

M

.020

.030

0.51

0.76

P

.314

.326

7.98

8.28

U

.025

.048

0.64

1.22

V

.045

.070

1.14

1.78

Conformance inspection, part 3 (see note 2)

A

3.335

3.365

84.71

85.47

B

.807

.817

20.50

20.75

D

2.250

2.300

57.15

58.42

E

2.195

2.380

55.75

60.45

F

3.410

3.550

86.61

90.17

N

.700

.800

17.78

20.32

R

55

65

55

65

S

115

125

115

125

T

.470

.530

11.94

13.46

NOTES:

1. Dimensions H, J, K, L, and M shall be maintained within .100 inch (2.54 mm) from the outer peripheral edge of the contact

tabs.

2.

Dimensions shall be checked yearly. A regular double sampling plan shall be used, with the first sample of three tubes with

an acceptance number of zero, and a second sample of three tubes with a combined acceptance number of one. In the event

of failure, the test will be made as a part of conformance inspection, part 2, acceptance level 6.5, and inspection level S3.

The regular yearly double sampling plan may be reinstated after three consecutive samples have been accepted.

FIGURE 2. Outline drawing of electron tube type 8660.

6