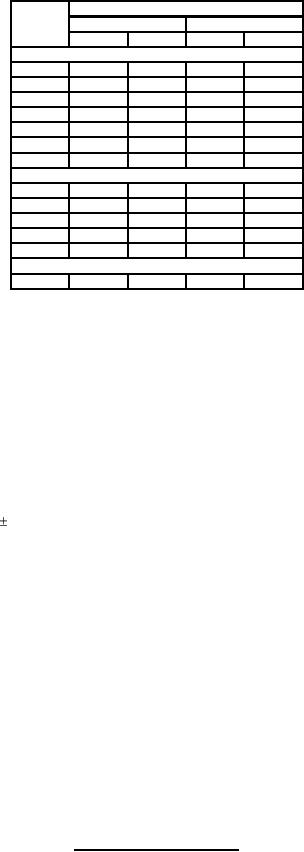

MIL-PRF-1/1624B(NAVY)

Dimensions

Ltr

Inches

Millimeters

Min

Max

Min

Max

Qualification inspection

A

.736

.764

18.69

19.41

B

.736

.764

18.69

19.41

C

.143

.157

3.63

3.99

H

1.673

1.687

42.49

42.85

K

.738

.762

18.75

19.35

L

1.365

1.385

34.67

35.18

M

1.122

1.128

28.50

28.65

Conformance inspection, part 1

E

.698

.699

17.73

17.75

F

.020

.024

0.51

0.61

G

1.679

1.693

42.65

43.00

J

.891

.909

22.63

23.09

P

.120

.130

3.05

3.30

Conformance inspection, part 2

D

.590

.602

14.99

15.29

NOTES:

1 Diameter "R" shall be concentric with reference diameter "Z" within 0.004 T.I.R.

2. Surface "N" shall be perpendicular to surface "X" within 0.010 T.I.R.

3. A plane passing through the axis of diameters "Y" at surface "N" shall be perpendicular to surface "X" within 0.010 T.I.R.

4. For pressurization of the choke flange, use an AMS 3303-13 "O" ring, or equivalent.

5. For pressurization of the circular waveguide flange, use an AMS 3303-18 "O" ring, or equivalent.

6. All surfaces other than the flange faces shall be painted semi-gloss gray conforming to FED-STD-595, color 26373.

7. Electrical parameters:

a. Center frequency: 33.2

0.3 GHz.

b. VSWR: 1.15 (maximum) over frequency range of 32.9 to 33.5 GHz.

c. Mode purity: 20 dB (minimum) over frequency range of 32.9 to 33.5 GHz.

d. Pressurization: 40 psig (maximum).

e. Power handling capability: 100 kW peak 40 watt average at 15 psig dry air.

f. Insertion loss: 0.3 dB (maximum).

g. Pressure leakage: There shall be no bubbles when immersed in water and pressurized up to 40 psig for 1 minute.

FIGURE 2. Circular to rectangular transition - Continued.

12

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business