MIL-PRF-1/1385K

Dimensions

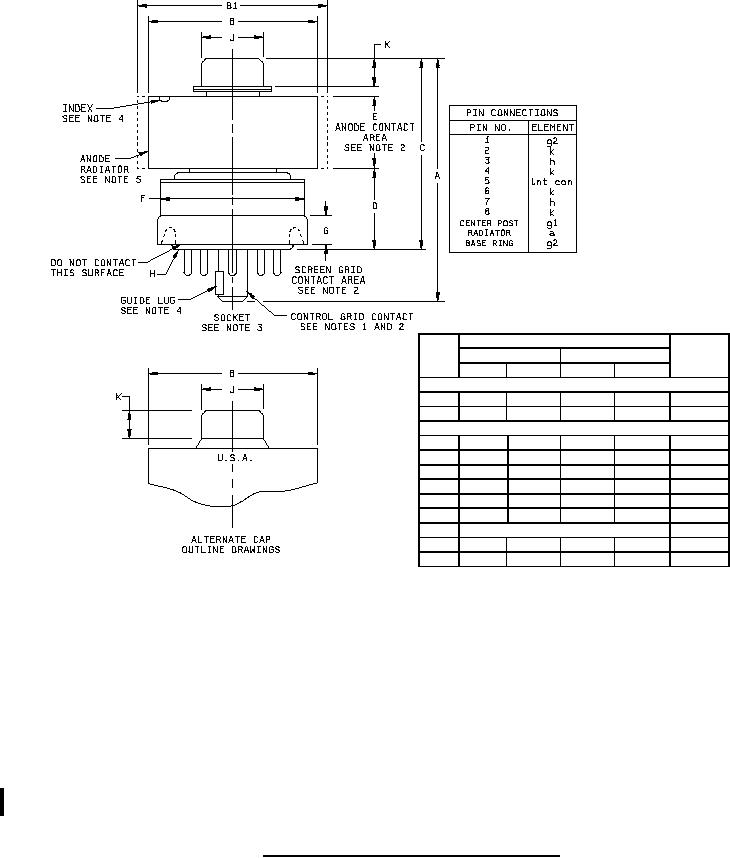

Ltr

Inches

Millimeters

Tube

Min

Max

Min

Max

type

Conformance inspection, part 2

A

2.324

2.464

59.03

62.59

Both

C

1.810

1.910

45.97

48.51

Both

Conformance inspection, part 3 (see note 6)

B

1.610

1.640

40.89

41.66

7580W

B1

2.050

2.080

52.07

52.83

8930

D

.750

.810

19.05

20.57

Both

E

.710

.790

18.03

20.07

Both

F

---

1.406

---

35.71

Both

G

.187

---

4.75

---

Both

H

Base: B8: 236 (EIA) (see note 1)

Both

J

.559

.573

14.20

14.55

Both

K

.240

---

6.10

---

Both

NOTES:

1. Pin alignment shall be checked by means of JEDEC gauge GB8-3. Dimensions of control-grid contact shall be inspected

by means of gauge specified on Drawing 246-JAN and shall be conformance inspection, part 2.

2. Alignment of anode, screen-grid, and control-grid contact surfaces shall be determined by means of gauge specified on

Drawing 168-JAN. Conformance inspection, part 2, shall apply. (Applies to tube type 7580W).

3. Air system socket shall be as specified on Drawing 246-JAN.

4. Location of guide lug of control-grid contact shall be referenced by a notch or arrow on the anode radiator in position

shown.

5. Anode clamping shall be confined to anode radiator.

6. Dimensions shall be checked yearly. An accept on zero defect sampling plan shall be used, with sample of three tubes

with an acceptance number of zero. In the event of failure, the test will be made as a part of conformance inspection,

part 2, acceptance level 6.5 of MIL-PRF-1 Table III. The yearly sampling plan may be reinstated after three consecutive

samples have been accepted.

FIGURE 1. Outline drawing of electron tube types 7580W and 8930.

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business