MIL-PRF-1/1385K

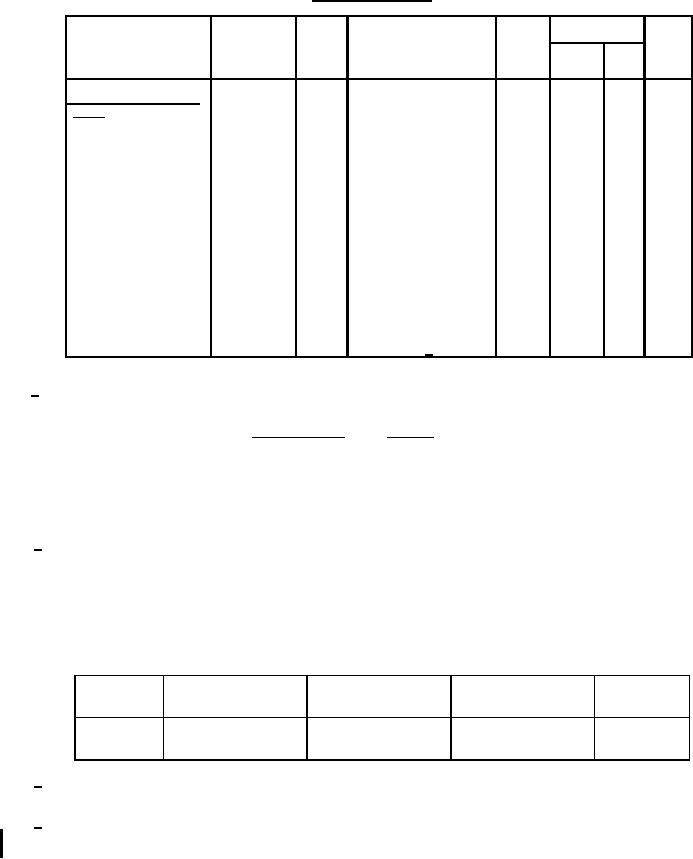

TABLE I. Testing and inspection - Continued.

Inspection

Method

Type

Conditions

Symbol

Limits

Unit

MIL-STD-1311

Min

Max

Conformance inspection,

part 3 - Continued

Shock, specified pulse

---

end points:

µA dc

Total grid current

1266

Ic1

---

-20

1261

Ec1

-70

-100

Electrode voltage (grid)

V dc

2204

7580W Eb = 2,000 V dc;

Po

250

---

W

Linear amplifier power

(useful)

output and distortion

Ec2 = 400 V dc;

Ec1/Ibo = 75 mA dc;

dB

3rd IM

-22

---

Eg1/Ib = 250 mA dc 1-tone; 5th IM

dB

-27

---

RL = 4,000 ± 100 ohms;

Rg = 1,000 ohms (max);

F = 2 MHz (min),

10 Mhz (max); anode

tank Q = 10 to 15;

t = 180 (min) 4/

1/

To obtain maximum life, it is necessary to adjust heater voltage to values indicated below at the indicated frequencies of

operation. These figures are for straight-through amplifier operation. In no case shall the heater be operated at less than 5.4

volts.

Frequency (MHz)

Ef (V ac)

300 or lower

6.00

301 to 400

5.75

401 to 500

5.50

It is recommended that the heater voltage be maintained within ± 5 percent when consistent operation and extended tube life

are factors. This applies to both nominal and derated voltages.

At the specified anode dissipation and an incoming air temperature of 25°C maximum, a minimum airflow, as specified, shall

2/

pass through the anode cooler. At this flow-rate, the static pressure drop across the tube and socket, with an appropriate

chimney (air director) around the anode cooler, is approximately as specified below. The pressure drop varies with the

amount of escaping air and with the shape and construction of the air director. This rating applies at bias voltages less than

100 volts and frequencies less than 500 MHz. Air cooling on the tube base shall be increased with increasing negative grid

bias or with increasing frequency, or a combination of both. In all cases of operation, a socket which provides forced-air

cooling shall be used and maximum seal and anode core temperature ratings shall not be exceeded. The airflow shall be

applied before or simultaneously with electrode voltages, and may be removed simultaneously with them. Where emphasis is

placed on long and reliable life, cooling in excess of minimum requirements shall be used.

Anode dissipation

Airflow

Static pressure

Type

(watts)

(cfm)

drop (inch of water

Socket

at sea level)

7580W

250

3.8

0.30

246-JAN

8930

350

6.0

0.60

246-JAN

3/

In all electrical tests involving application of heater voltage, the use of an air-system socket and forced-air cooling is

permissible.

4/

This test shall be performed yearly. An accept on zero defect sampling plan shall be used, with sample of three tubes with an

acceptance number of zero. In the event of failure, the test will be made as a part of conformance inspection, part 2,

acceptance level 6.5 of MIL-PRF-1 Table III . The yearly sampling plan may be reinstated after three consecutive samples

have been accepted.

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business