MIL-PRF-1/1295F

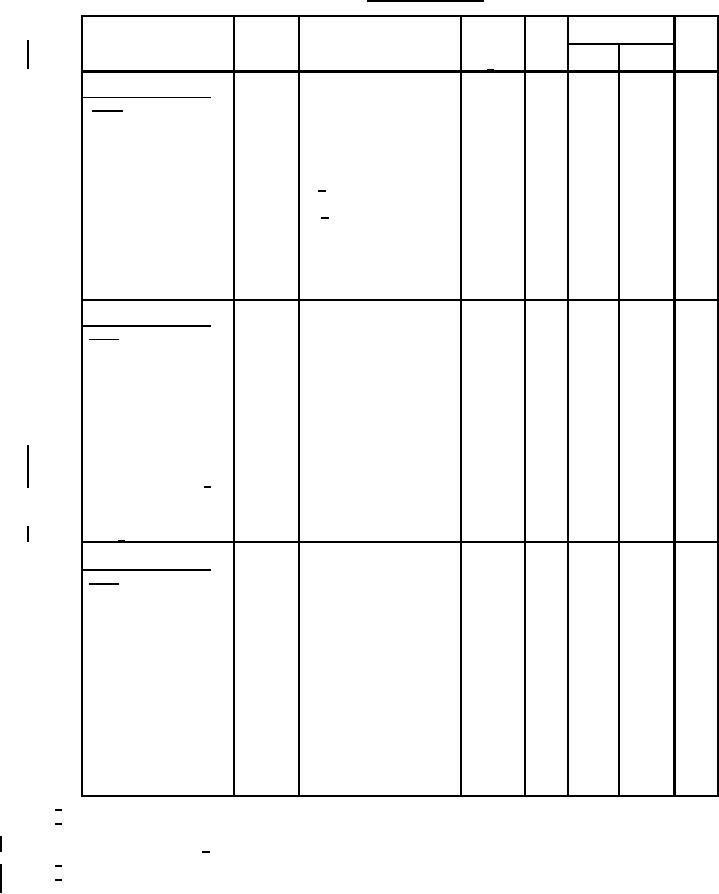

TABLE I. Testing and inspection.

Inspection

Method

Conditions

Acceptance Symbol

Limits

Unit

MIL-STD-

Level

4/

Min

Max

1311

Conformance inspection,

part 1

mA

165

135

If

---

1301

Heater current

Heater-cathode leakage

1336

1

Ihk

---

50

Ehk = ±100

µA dc

1/

1

Ic1

---

-0.3

Total grid current

1266

µA dc

1/

1

Ib

2.6

4.5

mA dc

1256

Electrode current (1)

(anode)

Electrode current

1256

1

Ic2

---

1.0

mA dc

(screen grid)

Transconductance

1306

1

Sm

2,050

3,650

µmhos

Conformance inspection,

part 2

Electrode current (2)

1256

Ec1 = -10 V dc

2.5

Ibo

---

100

µA dc

(anode) (idling)

Cgp

1331

Unshielded

---

Direct-interelectrode

---

.040

PF

Cin

capacitance

3.0

5.0

pF

Cout

17.0

2.3

pF

High-frequency vibration 2/

1031

Rp = 2,000 ohms; no voltages

---

Ep

---

200

mV ac

Insulation of electrodes 2/

1211

---

---

---

---

---

Permanence of marking

1105

---

---

---

---

---

Shock 2/

1041

---

---

---

---

---

30° hammer angle

Conformance inspection,

part 3

Intermittent life

1501

Group D

---

t

500

---

Hrs

Eb = 3,000 V dc;

Ec2 = 100 V dc;

RK = 2,500 ohms;

Ehk = +100 V dc

-

---

Intermittent life test

end points (500 hours)

mA dc

---

2.0

---

---

1256

Electrode current (1)

(anode)

25%

---

---

1306

Transconductance

ĆSm

µmhos

(change of individual

t

tubes)

1/

This test shall be performed at the conclusion of the holding period.

2/

This test shall be conducted on the initial lot and thereafter on a lot approximately every 12 months. W hen one lot has passed, the

12-month rule shall apply. In the event of lot failure, the lot shall be rejected and the succeeding lots shall be subjected to this test

until a lot passes. (See 4/.)

3/

Revision letters are not used to denote changes due to the extensiveness of the changes.

4/

This specification sheet uses accept on zero defect sampling in accordance with MIL-PRF-1, table III.

2

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business