MIL-PRF-1/1203K

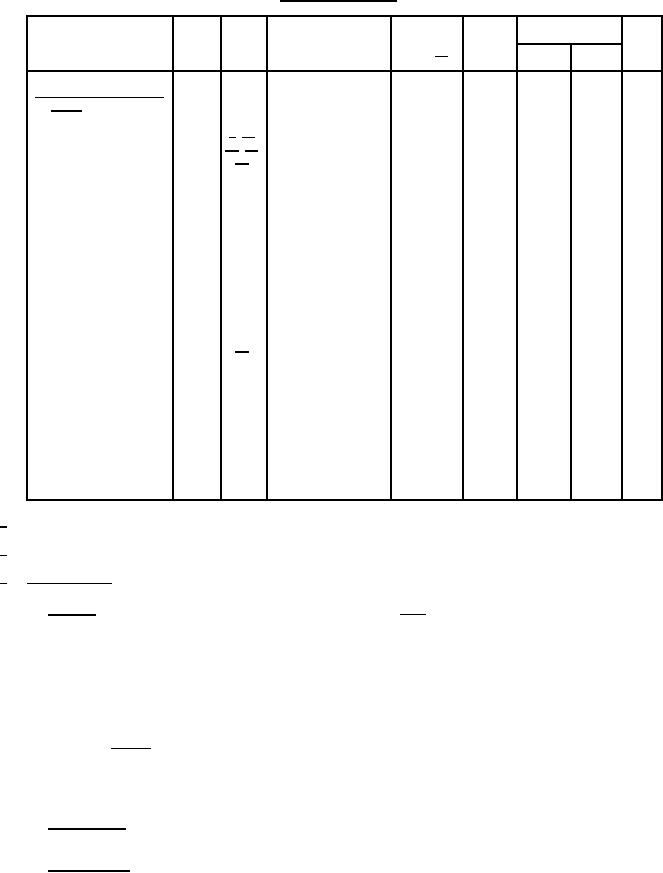

TABLE I. Testing and inspection - Continued.

Inspection

Method

Notes

Conditions

Acceptance

Symbol

Limits

Unit

Level 14/

Min

Max

Conformance inspection,

part 3 - Continued.

---

---

---

---

---

Intermittent life (2)

1501

9/ 10/ Stability-life test, or

11/ 12/ equivalent conditions,

13/ except TE = 250°C

(min); t = 1,000 hours

Intermittent life-test

---

end points:

Heater current

1301

---

---

mA

264

222

If

Noise figure (1)

---

---

dB

8.6

---

NF

---

Noise figure (2)

---

---

dB

10.5

---

NF

---

Power gain

---

---

dB

---

11.0

Gain

---

µA dc

Heater-cathode leakage

1336

---

20

---

Ihk

---

Insulation of electrodes

1211

---

---

50

R

---

Meg

µmhos

Transconductance (1)

1306

---

---

6,000

Sm

---

Hammer angle = 30°;

Shock

1041

13/

---

---

---

---

---

Ehk = 50 V dc;

Eb = 150 V dc;

Rp = 0

Shock-test end points

15

Ep

---

---

---

1031

mV ac

Low-frequency vibration

µA dc

20

Ihk

---

---

---

1336

Heater-cathode leakage

---

8.1

NF

---

---

---

Noise figure (1)

dB

11.5

---

---

Gain

---

---

Power gain

dB

At anode temperature below 150°C, Rg may be increased to 0.1 Meg.

1/

2/

Envelope temperature is defined as the temperature measured at the periphery of the anode.

3/

Noise figure test.

a. Definition. The noise figure of the system shall be defined as 10 log 32.4 , where 32.4 is the excess noise temperature of the

Y -1

noise generator, expressed as power ratio, and Y is the ratio of the noise power output of the system with the noise generator

"on" to the noise power output of the system with the noise generator "off". The specified test limits refer to the noise figure of

the tube under test (TUT) which is the noise figure of the system corrected for the noise figure of the noise amplifier and of the

first stage.

The first stage noise figure is calculated with the formula:

(F2 - 1) where F1 is the noise figure of the first stage, F2 is the noise figure of the noise figure amplifier, F1 -2 is

F1 = F1 -2 -

G1

the measured noise figure of the overall systems (all noise figures being expressed as power ratios rather than in decibels) and

G1 is the average gain of the TUT expressed as a power ratio.

b. Test procedure. Measurement of noise figure is made by noting the noise power in the calibrated power indicator both with the

noise generator switched "on" and with it switched "off", using the equipment shown on figure 2.

c. Noise generator. An Airborne Instrument Laboratory Argon Lamp Noise Generator, Model 70, or equivalent.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business