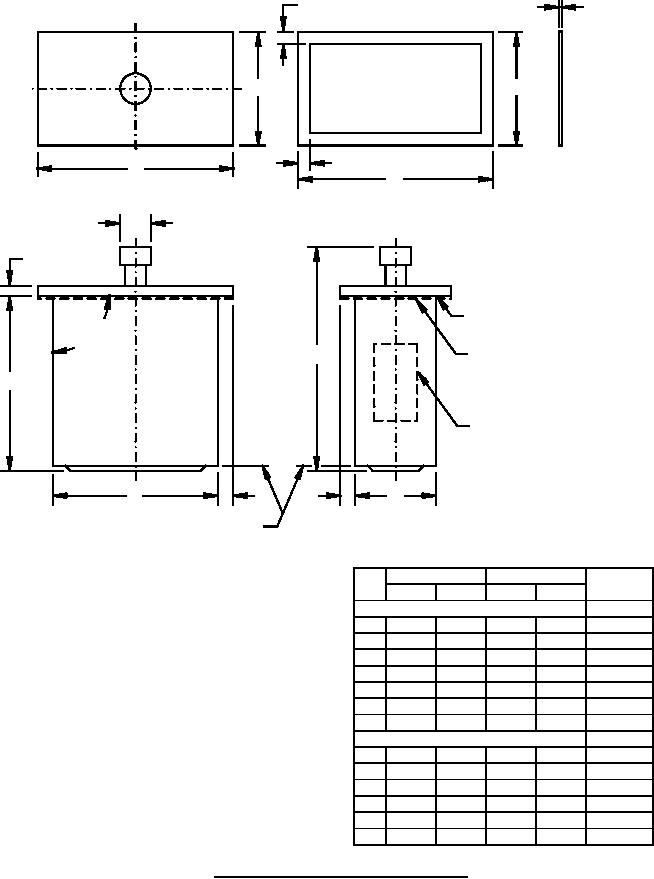

MIL-E-1/384C

M

R

N

B

M

A

P

GASKET

SEE NOTE 6

G

H

J RAD

90°

±5'

POSITION OF GASKET

C

WHEN MOUNTED

D

AREA "A"

SEE NOTE 5

F

F

K

E

SURFACE

"B"

Minimum

Maximum

Ltr

Notes

in

mm

in

mm

NOTES:

Conformance inspection, part 1

1. The tabulation shall fall within a circle of .500 in. (12.70 mm)

A 2.395 60.83 2.405 61.09

dia max located about the center of the flange.

B 1.395 35.43 1.405 35.69

2. Silver plate 100 msi min. or equivalent.

D 2.074 52.68 2.102 53.39

3. Applies at all edges of window face of tube at surface B.

E 1.985 50.42 2.015 51.18

4. Centerlines of window shall coincide with corresponding

F

.182

4.62

3

centerlines of the body within .015 in. (.38 mm) measured in

K

.985 25.02 1.015 25.78

plane of window.

P 2.395 60.83 2.405 61.09

5. Area A centrally located on barrel (see table 1, note 2).

Conformance inspection, part 2

6. Gasket is soft temper nickel or copper, two supplied with

C

2.750 69.85

tube but not mounted.

G

.375

9.53

H

.117

2.97

.133

3.38

J

.040

1.02

All sides

M

.145

3.68

.155

3.94

N 1.395 35.43 1.405 35.69

FIGURE 1. Outline drawing of electron tube type 6081.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business