MIL-E-1/175K

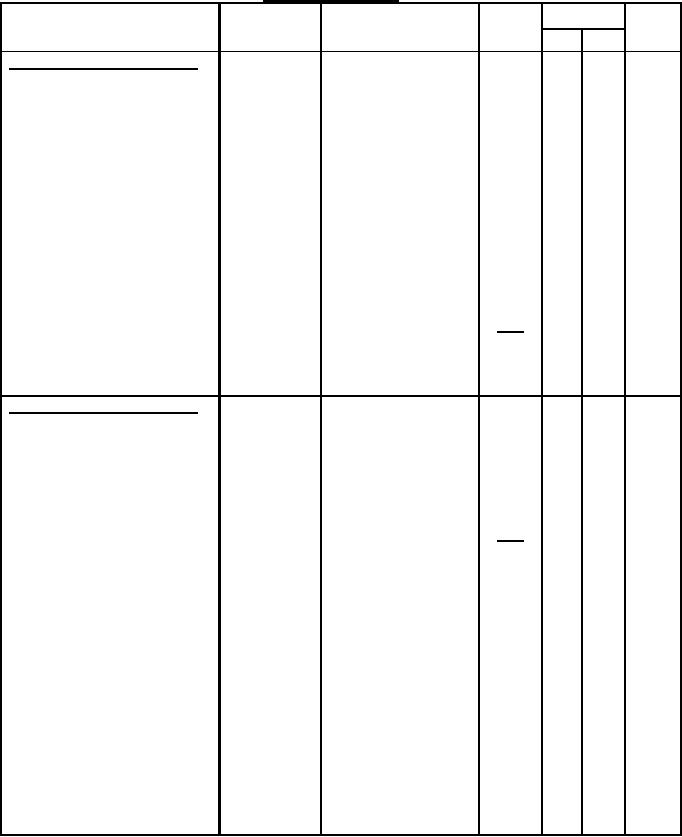

TABLE I. Testing and inspection - Continued.

Limits

MIL-STD-1311

Requirement or test

Units

Conditions

Symbol

Method

Min

Max

Conformance inspection, part 2 -

Continued

Envelope strain

2126

---

---

---

---

Shock

1041

450 G:

Ebk = +100 V dc;

Rg1 = 0.1 MegΩ

Vibration fatigue test

1031

2.5 G; fixed frequency;

---

---

---

---

F = 25 min, 60 max

Post-shock and vibration-fatigue

---

test end points:

Low-frequency vibration

1031

Ep

---

300

mV

ac

Heater-cathode leakage

1336

Ihk

---

40

ľA dc

ΔPo

Change in power output (1)

1341

---

20

%

of individual tubes

t

Permanence of marking

1105

---

---

---

---

Conformance inspection, part 3

Stability life test

1516

Eb = Ec2 = 100 V dc;

---

---

---

---

Ehk = +200 V dc;

Rgl = 0.47 MegΩ;

Rk = 220 ohms;

TA = room

Stability life test end point:

---

ΔPo

Change in power output (1)

1341

---

10

%

of individual tubes

t

Heater-cycling life test

1506

Ef = 7.0 V;

---

---

---

---

1 min "on";

4 min "off";

Ehk = 140 V ac;

Ecl = Ec2 = Eb = 0

Heater-cycling life-test end point:

---

Heater-cathode leakage

Ihk

---

40

ľA dc

Intermittent life test

1501

Stability life-test, or

---

---

---

---

(room temperature)

equivalent conditions;

TA = room

Intermittent life-test end point

---

(room temperature, 500 hours):

MegΩ

Insulation of electrodes

1211

R

50

---

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business