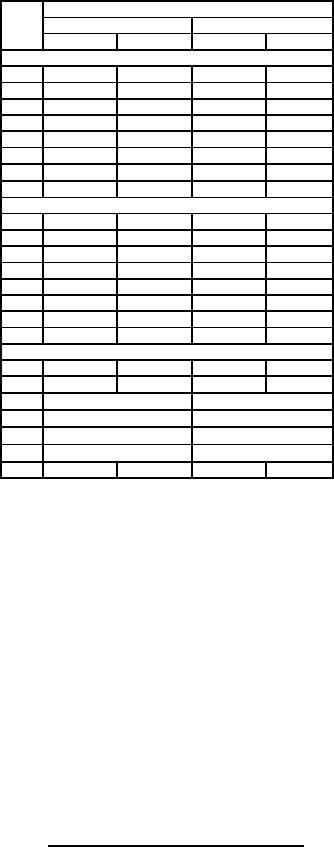

MIL-PRF-1/982D

Dimensions

Ltr

Inches

Millimeters

Min

Max

Min

Max

Conformance inspection, part 1

H

1.312

1.438

33.32

36.53

J

.330

.400

8.38

10.16

K

.135

.145

3.43

3.68

L

.910

.930

23.11

23.62

M

1.203

1.234

30.56

31.34

P

.656

.719

16.66

18.26

154°30'

160°30'

154°30'

160°30'

Z

AD

1.168

1.188

29.67

30.18

Conformance inspection, part 2

A

---

1.609

---

40.87

B

---

.859

---

21.82

F

1.000

1.016

25.40

25.81

G

---

3.562

---

90.47

N

.182

.192

4.62

4.88

R

.203

.234

5.16

5.94

S

.484

.516

12.29

13.11

U

---

.116

---

2.95

Qualification inspection

C

.767

.797

19.48

20.24

T

.766

.797

19.46

20.24

70°

V

---

70°

W

---

70°

X

---

70°

Y

---

AB

1.271

1.312

32.28

33.32

NOTES:

1. The tuning screw shall be lubricated with Oildag or equal non-corrosive lubricant. It shall be capable of being

operated smoothly through its entire range without perceptible binding.

2. The base shall be capable of being inserted in a gauge 1.219 (30.96 mm) thick having 4 holes .250 (6.35 mm)

deep from the top of the gauge whose diameters are .103 (2.62 mm) for the contact pins. Remaining portion of

hole to be clearance, approximately .016 (0.41 mm) larger in diameter and a fifth hole whose diameter .160

(4.06 mm) by 1.219 (30.96 mm) deep for the output lead. All holes located on the true center. Also a center

hole having the contour of the pilot but with the clearance of .002 (0.05 mm) over the maximum diameter.

3. Nickel (30 msi silver permissible).

4. Dimensions are in inches.

5. Metric equivalents are given for general information only.

FIGURE 1. Outline drawing of electron tube type 2K25 - Continued.

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business