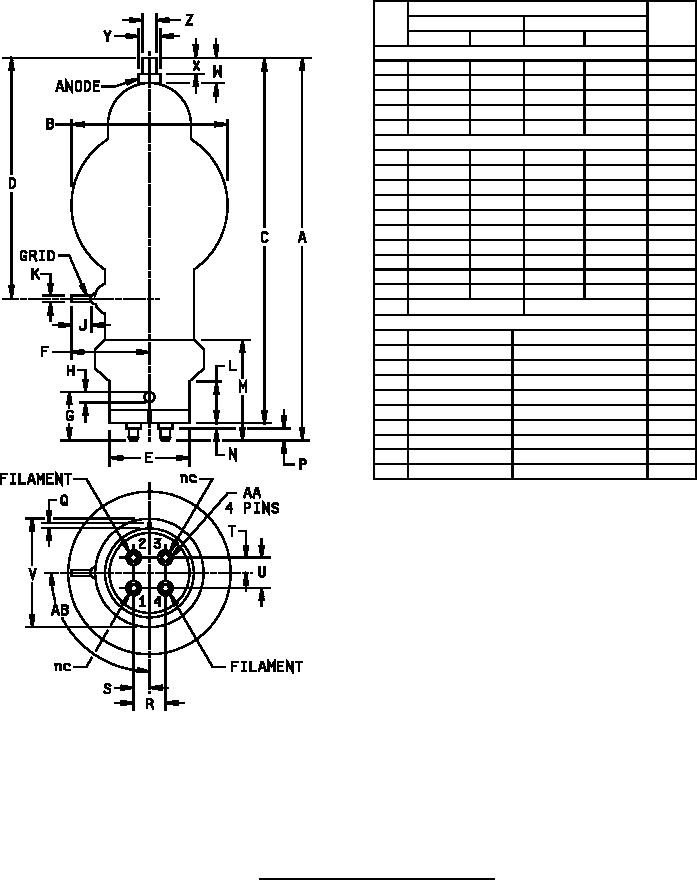

MIL-PRF-1/878G

Dimensions

Ltr

Inches

Millimeters

Notes

Min

Max

Min

Max

Conformance inspection, part 2

A

9.625

10.125

244.48

257.18

B

---

3.813

---

96.85

D

5.688

6.188

144.48

157.18

F

1.563

1.938

39.70

49.23

J

.312

---

7.92

---

Conformance inspection (periodic check) part 3

1

C

9.375

9.875

238.13

250.83

E

---

1.867

---

47.42

H

---

.082

---

2.08

K

.065

.071

1.65

1.80

P

.250

.320

6.35

8.13

2

Q

---

.109

---

2.77

V

---

2.500

---

63.50

X

.328

---

8.33

---

Z

.350

.365

8.89

9.27

AA

.185

.189

4.70

4.80

80°

100°

AB

Reference dimensions

G

1.225

31.12

2

L

1.938

49.23

M

2.719

69.06

2

N

.031

0.79

R

.688

17.48

S

.344

8.74

T

.344

8.74

U

.688

17.48

W

.563

14.30

Y

.500

12.70

NOTES:

1. This test shall be performed yearly, with sampling as follows:

n1 = 4

c1 = 0

where c2 represents the total failures for the

first and second samples combined.

n2 = 4

c2 = 0;

In case of failure, the test shall become a conformance inspection, part 2 test for three successive

successful submissions, at which time the test may revert to the yearly basis.

2. On finished tube, add .060 inch (1.52 mm) maximum for solder.

FIGURE 1. Outline drawing of electron tube type 250TH.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business