MIL-PRF-1/852E

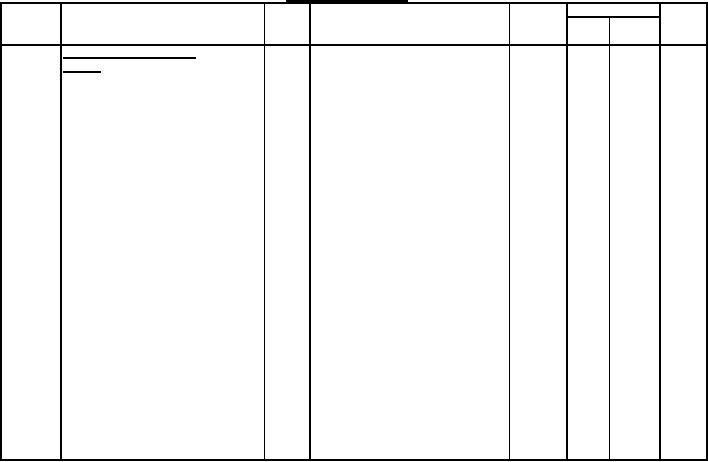

TABLE I. Testing and conditions - Continued.

Limits

MIL-STD-

1311

Requirement or test

Notes

Conditions

Symbol

Unit

Min

Max

method

Conformance inspection,

part 3 - Continued.

Intermittent life-test end points (500

hours):

Total grid current

1266

ľAdc

Ic1

0

-6.0

Heater current

1301

mA

If

800

1,010

ĆPo

Power oscillation (Ef = 5.7 V)

1236

%

---

15

Ef

ĆPo

Power oscillation (change in

1236

%

---

20

individual tubes)

t

Power oscillation (overage change)

1236

%

Avg

---

15

ĆPo

t

Heater-cathode leakage

1336

ľAdc

Ihk

---

150

MegΩ

Insulation of electrodes

1211

R

25

---

Total defectives

---

---

---

---

---

Intermittent life-test end points (1,000

---

hours):

Total grid current

1266

ľAcc

Ic1

0

-6.0

Heater current

1301

mA

If

800

1,010

ĆPo

Power oscillation (change in

1236

%

---

25

individual tubes)

t

Power oscillation (average change)

1236

%

Avg

---

20

,ĆPo

t

150

Heater-cathode leakage

1336

ľAdc

Ihk

---

MegΩ

---

Insulation of electrodes

1211

R

25

---

Total defectives

---

---

---

---

NOTES:

1.

This test shall be performed at the conclusion of the holding period.

2.

Prior to this test, the tubes shall be preheated a minimum of 5 minutes at the conditions indicated below. The 3-minute test

is not permitted. Test at specified conditions within 3 seconds after preheating. Grid emission shall be the last test

performed on the sample selected for the grid-emission test.

Ef

Rg1

Ec2

Ec1

Eb

V dc V dc V dc Meg Ω

V

0.01

300

-29

600

7.5

3.

Envelope-temperature (TE) requirements, when measured in accordance with the temperature by conduction-band

measurement (method 1226), will be satisfied if a TUT having bogey Ib (ą5 percent) under normal test conditions, is

determined to operate at or above minimum specified temperature at any position in the life-test rack.

4.

The test duration shall be of sufficient length to obtain a stabilized negative Isc2 value. Adjust Ec1 (0 to 6 V dc) to give Pg2

= 5 W. Pg2 shall be calculated as 2.48 times the product of the rectified current and rectified voltage. A protective resistor

of 15,000 ohms shall be placed in series with the primary emission current meter.

5.

This test shall be conducted on the initial lot and thereafter on a lot approximately every 12 months. When one lot has

passed, the 12-month rule shall apply. In the event of a lot failure, the lot shall be rejected and the succeeding lots shall be

subjected to this test until a lot passes. ANSI/ASQ Z1.4, sample size code letter E, shall apply.

6.

A grid resistor of 0.1 megohm shall be added; however, this resistor shall not be used when a thyratron-type short indicator

is employed.

7.

The life-test sample shall consist of 20 tubes per lot and not more than 1 tube failure shall be permitted. In the event of

rejection of the first sample, due to failure of more than 1 tube, a second sample of 40 tubes shall be selected from the lot.

Acceptance shall then be based on the combined first and second samples. The total tube failures from the combined first

and second samples shall not exceed three.

8. This specification sheet utilizes accept on zero defect sampling plan in accordance with MIL-PRF-1, table III.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business