MIL-PRF-1/812E

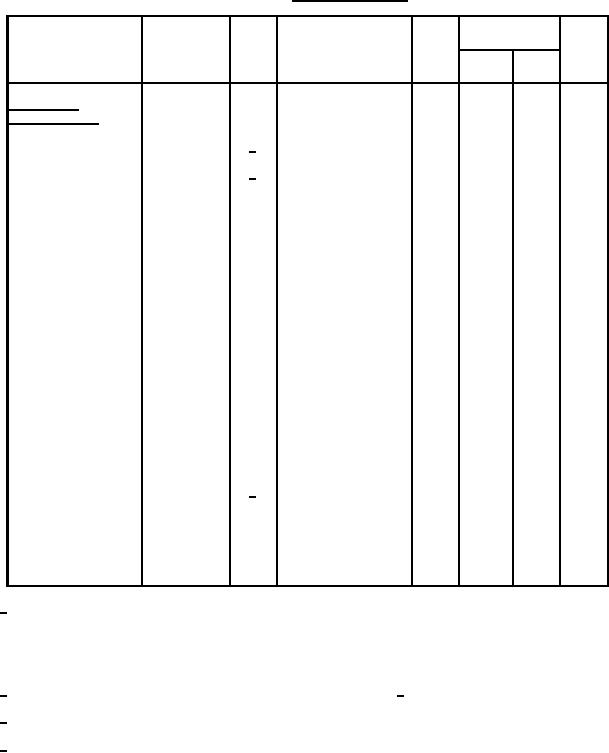

TABLE I. Testing and inspection - Continued.

Inspection

Method

Notes

Conditions

Symbol

Limits

Unit

MIL-STD-1311

Min

Max

Conformance

inspection, part 3

No voltages applied

Low-frequency vibration

1031

4/

---

---

---

---

1036

4/

Angle = 20°

---

---

---

---

Bump

Low-frequency vibration

---

and shock end points:

V dc

Electrode voltage

1261

---

Ec1

-65

-95

(grid)

Total grid current

ľA dc

1266

---

Ic1

---

-10

Life test

---

---

Group C; power

---

---

---

---

oscillation (1);

t = 500 hours

Life-test end points:

---

Peak emission

1231

---

is

4.0

---

a

Primary grid emission

ľA dc

1266

---

Isg1

---

-100

(control)

Primary grid emission

ľA dc

1266

---

Isg2

---

-200

(screen)

Total grid current

ľA dc

1266

---

Ic1

---

-10

Power oscillation (2)

1236

4/

Ebb = 3,000 V dc;

Po

350

---

W

(useful)

Ib = 200 mA dc;

Ec2 = 350 V dc;

Rg1 = 12,000 ohms;

F = 75 MHz

1/ Adequate cooling shall be provided for the seals and envelope of the tube. An air-system socket and air director (chimney) is desirable,

such as Eimac SK-400/SK-406 or SK-410/SK-406, or equal. At frequencies below 30 MHz, cooling air in the amount of 5 cfm around

the base of the tube past the envelope is required. At frequencies above 30 MHz, losses in the leads and envelope contribute to

heating, and additional cooling may be required. Cooling should be applied simultaneously with filament power, and in all cases there

should be some movement of air past the base and envelope.

2/ Cooling of the tube is permitted to an extent not to exceed that specified in 1/.

3/ This test shall be the first test performed at the conclusion of the holding period.

4/ This test shall be performed during the initial production and once each succeeding 12-calendar months in which there is production. A

regular double sampling plan shall be used, with the first sample of three tubes with an acceptance number of zero, and a second

sample of three tubes with a combined acceptance number of zero. In the event of failure, the test will be made as a part of

conformance inspection, part 2, code level D, with an acceptance level of 6.5. The regular "12-calendar month" double sampling plan

shall be reinstated after three consecutive samples have been accepted.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business