MIL-PRF-1/665F

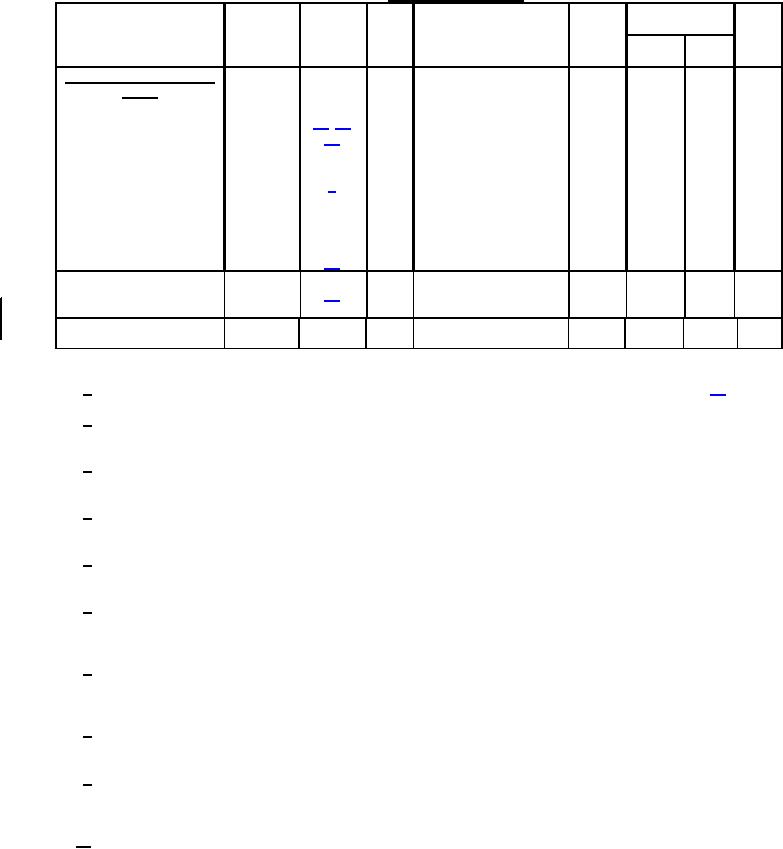

TABLE I. Testing and inspection.

MIL-STD-

1311

Limits

Inspection

Method

Notes

Test

Conditions

Symbol

Unit

Min

Max

Conformance inspection,

part 3

2

Group D

t

400

---

hrs

Life test

---

Life-test end points:

---

---

---

---

---

---

---

Fixed frequency

---

4/

2

F

2,750

2,860

MHz

W

---

3,600

Po

Power output

4250

---

1

W

---

2,880

Po

2

RF bandwidth

4308

---

BW

---

2.0

MHz

---

1.0

%

Pulse stability

4315

2

MP

Low-frequency

vibration

1031

---

---

No voltages

---

---

---

---

1/ Unless otherwise specified, the acceptance level for conformance inspection, part 1, shall be 1.0 (see 20/).

2/ The maximum value specified is for a non-oscillating condition. Heater surge current should not be allowed to

exceed 100 amperes.

3/ Frequency skipping or unstable operation may be encountered at some phase positions when the mismatch

occurs at the end of a "long" line.

4/ The anode and bushing temperature shall be measured at the points indicated on figure 1. The temperature

shall be measured after thermal equilibrium has been reached.

5/ During operation, the gas used in pressurization shall provide insulating properties at least equal to that of clean

dry air at the pressure indicated.

6/ Under test condition 1, or any other operating conditions in excess of 0.0008 duty cycle, it is essential to provide

a stream of air (5 cfm minimum) to cool the magnetron output window in order to prevent damage due to thermal

stresses.

7/ The characteristics of the applied pulse shall be those which result in proper starting and oscillation. The rate of

pulse voltage rise, the percentage of pulse voltage ripple, and the rate of pulse voltage fall are among the more

important considerations. Negative post-pulse voltage oscillations may cause leakage current and noise.

8/ The cathode terminal and high-voltage bushing shall be insulated by immersion in oil having the equivalent

electrical characteristics of ASTM-D3487.

9/ At all times the anode temperature shall be maintained at least 5°C above the freezing point of the anode liquid

coolant. Coolant pressure shall not exceed 55 pounds per square inch absolute, but sufficient pressure of

coolant shall be maintained to provide cooling of the anode to the temperature limits specified.

10/ In handling and mounting the magnetron, care shall be exercised to prevent demagnetization. Ferromagnetic

materials or energized magnets shall be kept more than 12 inches from the tube. Maintain 18 inches spacing

(center-to-center) to any other 6410A tube. Do not place an unpacked 6410A tube on a case containing another

6410A tube.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business