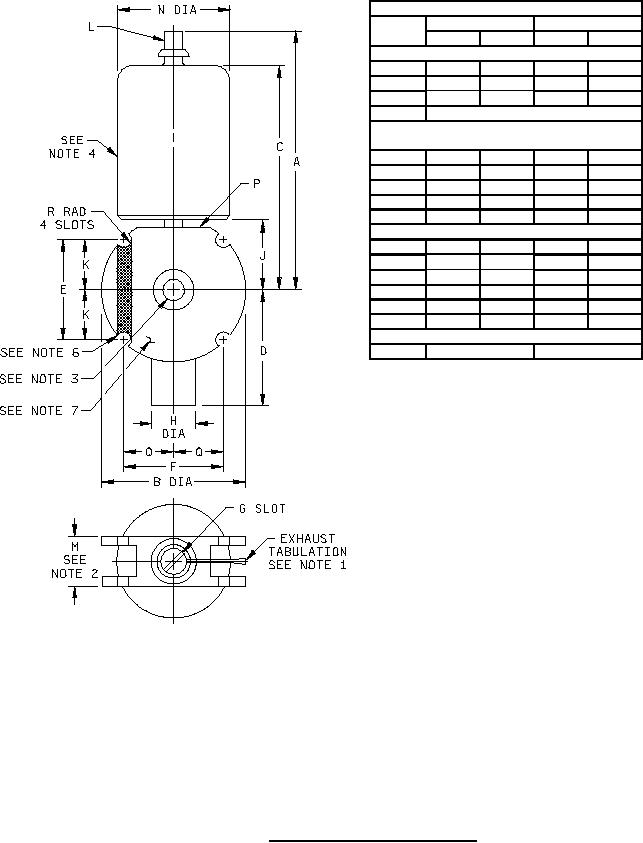

MIL-PRF-1/609G

Dimensions

Ltr

Inches

Millimeter

Min

Max

Min

Max

Qualification inspection

C

2.875

73.03

E

1.275

1.285

32.39

32.64

F

1.215

1.225

30.86

31.12

L

CAP: C1-2 (EIA)

Conformance inspection, part 1

(see note 1)

G

.031

.063

0.79

1.60

K

.637

.643

16.18

16.33

M

.609

.615

15.47

15.62

Q

.607

.613

15.42

15.57

R

.086

.094

2.18

2.39

Conformance inspection, part 2

A

3.250

82.55

B

1.760

44.70

D

1.422

36.12

H

.527

.533

13.39

13.54

J

.938

23.83

N

1.188

30.18

Reference dimension

P

.563 Flat

14.30 Flat

NOTES:

1.

Exhaust tubulation shall not extend beyond periphery.

2.

Applies to area between periphery of this section of tube and concentric circle of 5/16 radius.

3.

No part of iris assembly shall extend beyond body surface.

4.

Reservoir shall be glass, or approved equivalent.

5.

Maximum projection of reservoir shall lie within a cylinder of 1.250 diameter with axis colinear with tube axis.

6.

A force of 200 pounds shall be applied to the face of the tube within the area indicated by shading. Dimension M shall not

be permanently changed by more than 0.001. Qualification inspection required.

7. Body faces shall be cadmium plated 0.0003 minimum, or shall be made entirely of monel, bright nickel or equivalent. If nickel

Is required, it is recommended that it be used only when other metals can not meet the performance requirements.

8. Solder fillets permissible on peripheral surface near exhaust tubulation and electrode terminal. Slots shall be free from solder.

FIGURE 1. Outline drawing of electron type 1B24A.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business