MIL-PRF-1/343C

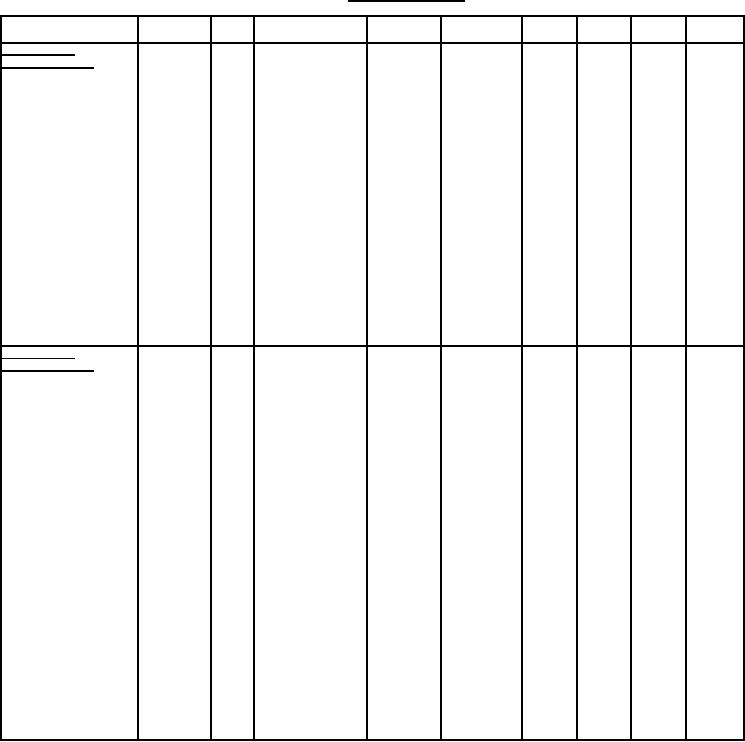

TABLE I. Testing and inspection.

Inspection

Method

Notes

Conditions

Acceptance

Inspection

Symbol

Limits

Limits

Unit

level

level or code

Min

Max

Conformance

inspection, part 1

µA dc

1266

2

Total grid current

1.0

II

Ic

0

-1.0

1341

2

Esig = 3.2 Vac;

Power output (2)

1.0

II

Po

140

---

mW

Ef = 1.1 V dc (prl);

Rp = 0.01 Meg

Electrode current

1256

---

1.0

II

Ib

6.5

12.5

mA dc

(anode)

Audio frequency noise

1246

1

Ecal (0 vu) =

1.0

II

EB

---

0

vu

2.63 Vac;

Ecal (50 mW)

= 400 mV dc;

Rg1 = 0.1 meg;

Rg2 = 1,000 Ω;

Ecc2 = 55 V dc;

Rp = 25,000 Ω;

Ef = 2.8 V dc

Short and discontinuity

1201

---

0.4

II

---

---

---

---

40 G

detection

Conformance

inspection, part 2

Filament current

1301

---

---

---

If

88

112

mA dc

Electrode current

1256

---

---

---

Ic2

1.3

3.1

mA dc

(screen grid)

µmhos

Transconductance

1306

---

Sm

2,500

---

---

1,800

Power output (1)

1341

---

Esig = 3.2 Vac;

---

---

Po

210

---

mW

Rp = 0.01 Meg

Direct-interelectrode

1331

---

capacitance

3Q4

---

---

---

0.41

pF

---

Cg1-p

3V4

---

---

---

0.40

pF

---

Cg1-p

3Q4

---

Without shield

---

3.8

7.2

pF

---

Cin

3V4

---

---

3.8

7.3

pF

---

Cin

3Q4

---

---

2.4

5.6

pF

---

Cout

3V4

---

---

2.2

5.4

pF

---

Cout

Rp = 2,000 Ω

Low-frequency vibration

1031

---

---

---

400

mV ac

---

Ep

Insulation of electrodes

1211

---

---

---

---

---

---

---

Base strain

1121

---

---

---

---

---

---

---

Glass strain

2126

---

---

---

---

---

---

---

Permanence of marking

1105

---

---

---

---

---

---

---

See footnotes at end of table I.

2

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business