MIL-PRF-1/334C

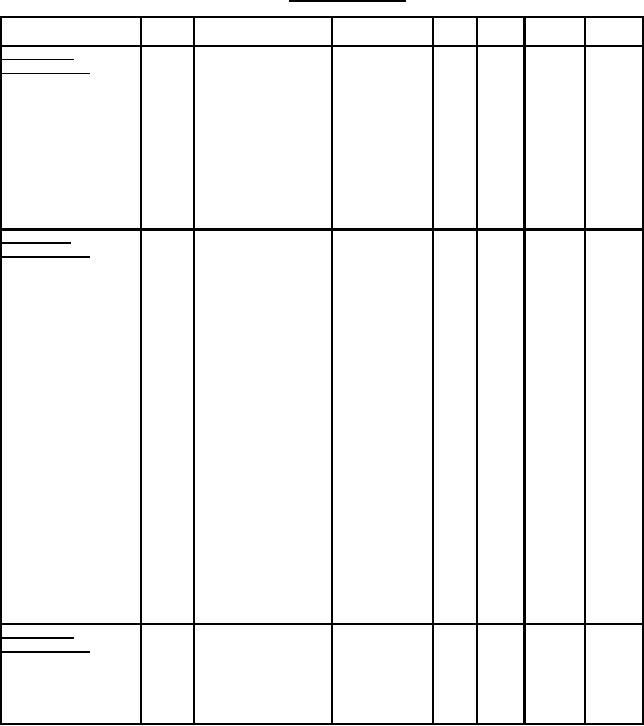

TABLE I. Testing and inspection.

Inspection

Method

Conditions

Acceptance level Symbol Limits

Limits

Unit

(see note 4)

Min

Max

Conformance

inspection, part 1

-0.5

0

Ic

0.65

Eb = 6,000 V, see note 2

1266

Total grid current

µA dc

---

32

Is

0.65

Eb = Ec = 30 V dc,

1231

Emission

mA dc

see note 2

1.6

0.9

Ik

0.65

T = 60; Eb = 6,000 V,

1256

Electrode current

mA dc

see note 3

(cathode)

---

---

---

---

0.4

1201

Short and discontinuity

detection

Conformance

inspection, part 2

mA

325

275

If

---

1301

Heater current

30

---

Ihk

---

1336

Heater-cathode leakage

µA dc

1,125

675

Sm

---

Eb = 1,500 V dc;

1306

Transconductance

µmhos

Ec = -1 V dc; Rk = 0

520

380

Mu

---

Eb = 1,500 V dc;

1316

Amplification factor

---

Ec = -1 V dc; Rk = 0

0.90

0.60

Cgp

---

No shield

1331

Direct-interelectrode

pF

6.0

4.0

Cin

capacitance

pF

2.6

1.2

Cout

pF

---

---

---

---

1211

Insulation of electrodes

---

200

---

Ep

---

Eb = 300 V dc; Ec = 0;

1031

Low-frequency vibration

mV ac

Rp = 10,000 Ω

---

---

---

---

1111

Base pin solder depth

---

---

---

---

---

1101

Secureness of base, cap,

---

or insert

---

---

---

---

1105

Permanence of marking

---

Conformance

inspection, part 3

---

---

---

---

---

Group C; Ehk = 300 V

---

Life-test provisions

mA dc

---

0.75

Ik

---

Electrode current

---

Life-test end point

(cathode)

(500 hours)

NOTES:

1. See "Reduced pressure (altitude) rating," and altitude maximum peak voltage.

2. This test to be performed at the conclusion of the holding period.

3. Initial arcing may be tolerated, but tubes shall be free of arcing at the conclusion of the test.

4. This specification sheet uses accept on zero defect sampling plan in accordance with MIL-PRF-1, table III.

2