MIL-PRF-1/297E

NOTES:

1. Output flange to be concentric with the open end of

Dimensions in inches with metric

the guide to within 0.010 inch (0.25 mm).

equivalents (mm) in parentheses.

2. The jack holes shall be within a radius of 0.023

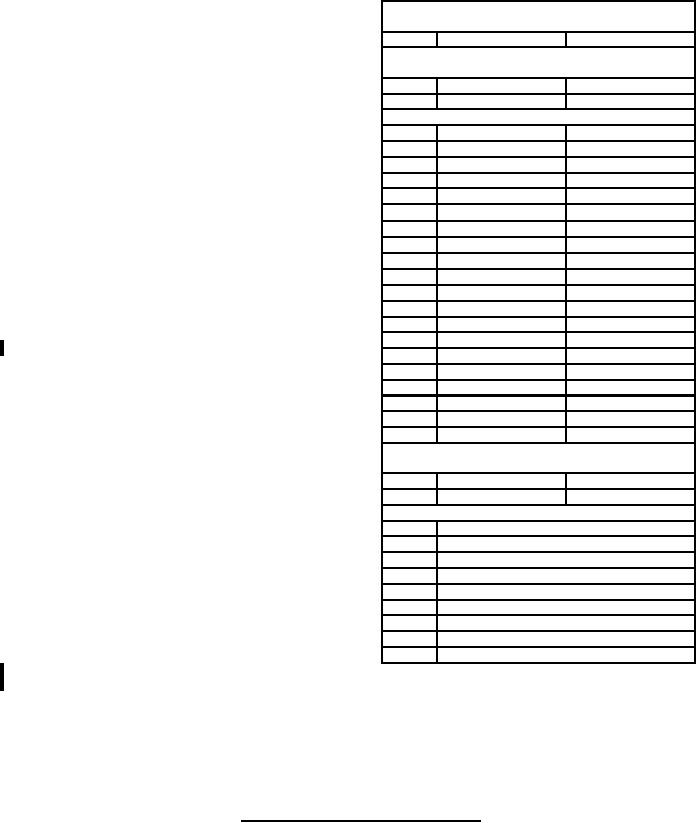

Ltr

Minimum

Maximum

inch (0.58 mm) of true location specified but shall be

Conformance inspection, part 1

spaced 0.500 inch (12.70 mm) 0.010 inch

(see note 1 Page 3)

(0.25 mm) with respect to each other. The center

J

0.417 (10.59)

0.457 (11.61)

lines of the holes shall be perpendicular to

Z

1.743 (44.27)

1.757 (44.63)

reference plane `A' within 3.

Conformance inspection, part 2

3. Pyrex glass, porcelain, or approved equivalent.

A

5.375 (136.53)

4. Indicate common cathode connection by letter C.

B

0.500 (12.70)

5. With the flange resting on a plane surface, the

E

3.125 (79.38)

flatness of the mounting plate 0.500 inch

H

2.500 (63.50)

(12.70 mm) from the outer edge shall be such that

K

0.080 (2.03)

0.090

(2.29)

a 0.010 inch (0.25 mm) thickness gauge 0.125 inch

59 48'

60 12'

L

(3.18 mm) wide shall not enter for a distance of

M

2.869 (72.87)

2.881 (73.18)

more than 0.250 inch (6.35 mm).

59 48'

60 12'

N

6. Metal surfaces shall be covered by painted finish

except inside of waveguide, jack terminals and

T

0.190 (4.83)

0.196 (4.98)

surfaces, covered by note 10.

U

2.745 (69.72)

7. Filament leads shall be flexible and slack.

W

2.661 (67.59)

8. Tolerance includes angular as well as lateral

X

1.172 (29.77)

1.212 (30.78)

deviations of the surface.

Y

0.432 (10.97)

9. Output to mate with UG52B/U flange

AB

0.859 (21.82)

0.891 (22.63)

(MIL-DTL-3922/59).

AF

2.922 (74.22)

3.047 (77.39)

10. Shall be free from paint.

AG

3.219 (81.76)

3.281 (83.34)

11. Leads soldered to terminal clip.

AH

2.969 (75.41)

12. All joints in waveguide assembly shall be vacuum

AJ

0.875 (22.23)

0.937 (23.80)

tight to provide hermetic seal at flange.

AK

0.875 (22.23)

0.937 (23.80)

13. All joints in mounting plate shall be vacuum tight

AL

1.406 (35.71)

1.468 (37.29)

to provide hermetic seal.

14. Heater connection.

Conformance inspection, part 3

15. Any portion of the assembly extending above this

(periodic check)

surface shall be within a 1.109 inch (28.17 mm)

AD

1.542 (39.17)

1.582 (40.18)

radius of the true center of the plate.

AE

0.120 (3.05)

0.130 (3.30)

16. Anode temperature measurement point.

Reference dimensions

17. Radiator fins.

C

0.062 (1.57)

18. Reference plane A is defined as a plane passing

D

1.344 (34.14)

along the surface of mounting plate as shown.

F

0.374 (9.50)

19. Reference plane B is defined as a plane passing

G

1.344 (34.14)

through the center of the two mounting plate

P

1.687 (42.85)

holes at plane A and is perpendicular to plane A.

R

1.187 (30.15)

20. Reference plane C is defined as a plane passing

S

1.245 (31.62)

through the center of the mounting plate hole

V

2.057 (52.25)

(as shown) at plane A and is mutually

AC

0.750 (19.05)

perpendicular to planes A and B.

21. Dimensions are in inches. Metric equivalents are in

parentheses.

FIGURE 1. Outline drawing of electron tube type 2J55 - Continued.

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business