MIL-PRF-1/290E

TABLE I. Testing and Inspection. -Continued.

MIL-STD-

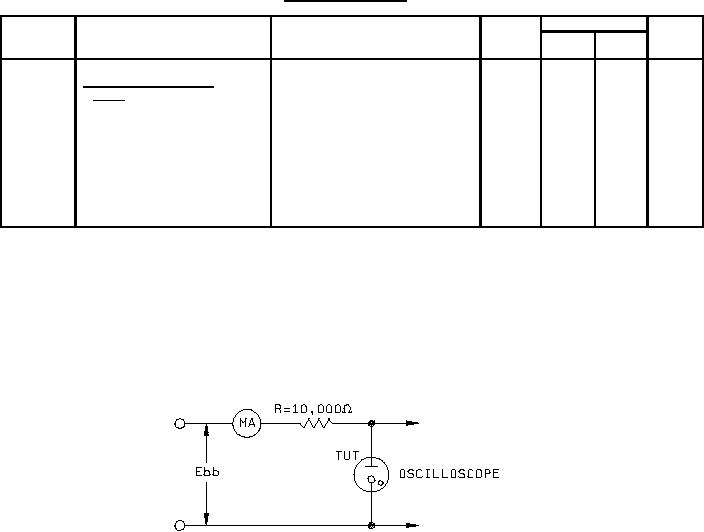

Limits

1311

Unit

Requirement or test

Conditions

Symbol

Min

Max

method

Conformance inspection,

part 3 - Continued

Life-test end points

---

Regulation

---

Reg

±8

V dc

(1,000 hours)

Voltage drop (1)

140

Etd

158

V dc

Voltage drop (2)

140

Etd

158

V dc

Voltage drop (3)

140

Etd

158

V dc

Change in voltage drop (3) of

Etd

---

8

V dc

individual tubes

Ionization voltage (1)

Ez

---

165

V dc

NOTES:

1. Sampling shall be in accordance with accept on zero defect sampling plan in MIL-PRF-1, table III, using the acceptance level

tabulated above.

2. This test to be performed at the conclusion of the holding period.

3. Vary current from 5 mA dc to 30 mA dc and back to 5 mA dc (by adjusting Ebb slowly). Sudden jumps registered on the

oscilloscope shall be not greater than the specified value.

4. Conditions for this test shall be those of ionization voltage (1), except testing shall be done in total darkness and the tube shall

not have conducted or been exposed to light for at least 24 hours prior to testing. The tube shall fire within 20 seconds

maximum.

5. The tube shall be tested in the following manner:

a.

The voltage drop shall be read at 10 mA dc drain.

b.

The tube shall be turned off for 1 minute.

c.

The tube shall be restarted and operated at the same current.

d.

Etd shall be read after 1 minute of operation.

e.

The "on-off" cycle shall be repeated a minimum of five times. The maximum difference in tube voltage drop shall be

taken as the measure of repeatability.

6. This test shall be conducted on the initial lot and thereafter on a lot approximately every 6 months. When one lot has passed,

the 6-month rule shall apply. In the event of lot failure, the lot shall be rejected and the succeeding lots shall be subjected to

this test until a lot passes.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business