MIL-PRF-1/273K

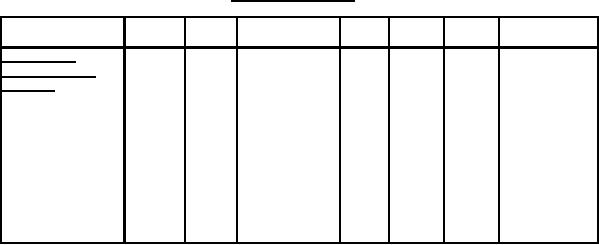

TABLE I. Testing and inspection - Continued.

Inspection

Method

Type

Conditions

Symbol

Limits

Limits

Units

Min

Max

Conformance

inspection, part 3

continued

mm

0.75

---

W idth

Line width A

1A, 1B

---

Life test end points

mm

0.85

---

W idth

Line width B

V dc

45

---

Modulation

ĆEc

V dc

55

---

12

Ib3 = 60 µA dc;

ĆEc

modulation

mm

0.40

---

W idth

Ib3 = 5 µA dc;

Line width A

mm

0.45

---

W idth

Ib3 = 5 µA dc;

Line width B

NOTES:

1. The construction of this gun shall be the zero Ib1 type. The following information and materials are to be available with

the four regular samples when application for qualification approval is made.

(a)

The electron gun drawing with significant dimensions.

(b)

A sample of the electron gun to be used in manufacture of tubes.

2. This test to be performed at the conclusion of the holding period.

3. The test is made with maximum voltage (Eg1 maximum negative voltage) applied to the base pins, and deflection

electrodes if applicable, only; and pressure of 87 mmHg. Connections should be made in a manner that does not

degrade the tubes electrical voltage breakdown characteristics. Satisfactory operation is the absence of arc-over and

corona.

4. P12 screen. The tube can be severely and permanently damaged if the current density on the screen is allowed to rise

too high in static tests of this sort . For this reason the length of time during which the screen is bombarded should be

kept as short as possible compatible with the readings of specified current limits.

5. The deflecting plates shall be returned to anode No. 2 through a minimum of 2.5-megohm resistors. The light output

shall be set at 15-ft lamberts (51.4 cd/m2). The high-frequency scanning shall be applied to the deflecting plates

nearest to the screen and the amplitude shall be adjusted to give a length of approximately 90 percent of the maximum

tube diameter. The low-frequency scanning amplitude shall be expanded to approximately 90 percent of the maximum

tube diameter, in the direction perpendicular to the direction of high-frequency scanning. Readjustments may be made

for best overall focus. The tubes shall be observed for deflection focusing, astigmatism, or spot ellipticity observable to

the eye as evidenced by fuzziness due to the lack of sharpness of trace (usually around edges), bow-tying (irregular

width of any single line when observed at different points), bowing of trace, other than that caused by curvature of

bulb. Such defects shall not be excessive as determined by the government representative. This test for focus is to be

made in addition to the line width measurements.

6. The same conditions shall be set up as described in note 5, except that the connection of deflecting elements to the

low- and high-frequency scanning supplies shall be interchanged and the amplitudes adjusted to 90 percent of the

maximum tube diameter in both directions without any adjustments of focus. An examination for defocusing,

astigmatism, or spot ellipticity shall be made as in note 6 and the defocusing, astigmatism, etc., shall not be excessive

as determined by a Government representative .

7. P12 screen. All tests except screen persistence and fluorescent brightness can be made at 50 percent duty cycle

pulsing .

8. Revision letters are not used to denote changes due to the extensiveness of the changes .

9. This specification sheet uses accept on zero defect sampling plan in accordance with MIL-PRF-1, table III.

5