MIL-PRF-1/21D

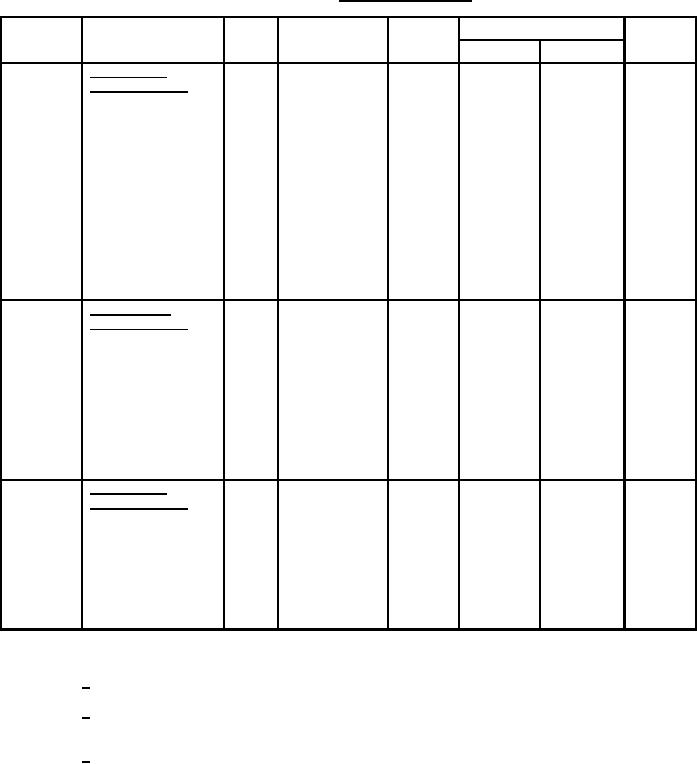

Table 1. Testing and Inspection.

Requirement or

Notes

Conditions

Symbol

Units

Limits

MIL-STD-

test

1311

MIN

MAX

method

Conformance

inspection, part 1

---

0.55

---

Po2/Po1

5

---

Water-vapor content

sec

5.0

t

Ebb = -800Vdc;

-

4401

Ignitor ignition time

R = 3.25 MegΩ

Ii = 100 μA dc

V dc

525

375

Eid

-

4406

Ignitor voltage drop

dB

1.6

---

Li

3

4416

Insertion loss

MHz

955.5

936.5

F

1, 8

---

Tuning

%

100

---

---

4

4478

High-level protection

Conformance

inspection, part 2

---

---

---

---

-

4021

Degradation due to

vibration

---

---

---

---

-

Dielectric material

4101

strain

μA dc

70

---

Ii

2

Ignitor current

---

ΔLi

Ii = 200 μA dc

0.2

---

-

Ignitor interaction

4421

dB

Conformance

inspection, part 3

hrs

---

500

t

Group C

6

---

Life test

---

Life-test end points:

ΔLi

Ii = 200 μA dc

Db

0.2

---

-

4421

Ignitor interaction

---

0.8

---

5

---

Water-vapor content

Po2/Po1

NOTES:

1/

This measurement shall be made with the tube mounted in test cavity according to Drawing 162-JAN.

2/

No tube shall require more than the stated maximum ignitor current to prevent relaxation oscillations

when tested in the standard circuit.

3/

This measurement shall be made in test cavity according to Drawing 162-JAN. With the cavity

calibrator in position, the cavity shall be tuned to resonance and the relative transmitted power

level noted. With the tube inserted, the cavity shall then be tuned to resonance and the transmitted

power noted. The dB loss in transmitted power due to the insertion of the tube shall not be more

than the specified amount.

2

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business