MIL-PRF-1/195D

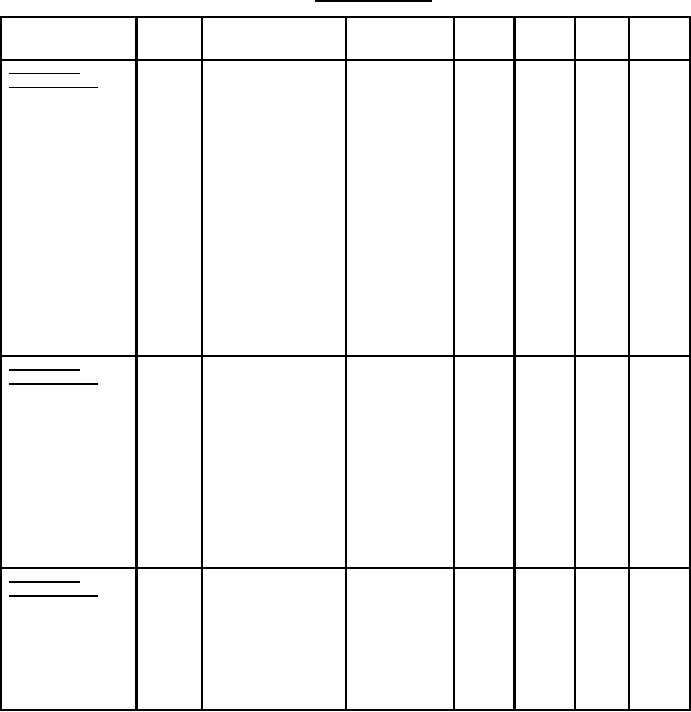

Table I. Testing and inspection.

Inspection

Method

Conditions

Acceptance

Symbol

Limits

Limits

Unit

Level (see note 6)

Min

Max

Conformance

inspection, part 1

V dc

125

---

0.65

Ez

Ionization voltage (1)

3347

Rp/Ib = 5 to 30 mA dc

(see notes 3 and 4)

V dc

---

80

0.65

Etd (1)

Voltage drop (1)

3337

Rp/Ib = 5 mA dc

V dc

100

0.65

---

Etd (2)

Voltage drop (2)

3337

Rp/Ib = 30 mA dc

V dc

6.0

---

0.65

Reg

Regulation

3335

Etd (2) - Etd (1)

---

---

0.65

---

---

Noise and oscillation

3278

Esig = 100 mV ac;

(oscillation test)

RL = 500; Ebb/Ib =

5 to 30 mA dc

mV ac

15.0

---

0.65

3278

Noise and oscillation

Ebb/Ib = 30 mA dc;

ĆEB

RL = 500

(noise)

---

---

---

0.4

1201

Short and discontinuity

---

detection

Conformance

inspection, part 2

---

---

---

---

6.5

No voltage

1031

Low-frequency

vibration

10.0

---

LIb

6.5

Eb = 50 V dc

3305

Leakage current

µA dc

---

---

---

6.5

1101

Secureness of base

---

and base insert

---

---

---

6.5

(See note 5)

1111

Base pin solder depth

---

Permanence of

---

---

---

---

1105

marking

---

Conformance

inspection, part 3

---

---

---

---

---

Group A;

---

Life-test provisions

Rp/Ib = 30 mA dc

V dc

130

---

Ez

---

Ionization voltage

---

Life-test end points

V dc

---

77

Etd (1)

---

Voltage drop (1)

(500 hours)

V dc

103

---

Etd (2)

---

Voltage drop (2)

V dc

9.0

---

Reg

---

Regulation

NOTES:

1. Pins 3 and 7 tied internally.

2. Fixed resistor may be used and Ebb varied to give desired current.

3. Test to be conducted with the tube exposed to light intensity of 5 to 50 footcandles.

4. This test to be performed at the conclusion of the holding period.

5. This test applies to flexible leads as well as for rigid leads.

6. This specification sheet uses accept on zero defect sampling plan, in accordance with MIL-PRF-1, table III.

2