MIL-PRF-1/193E

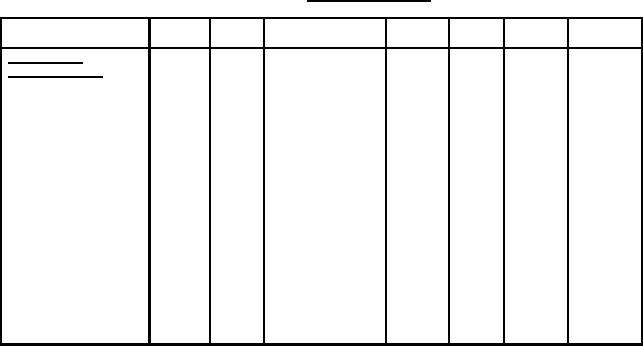

Table I. Testing and Inspection. -Continued

Inspection

Method

Notes

Conditions

Symbol

Limits

Limits

Unit

Min

Max

Conformance

inspection, part 3

---

---

---

---

Group A;

-

---

Life test

Rp/Ib = 30 mA dc

---

Life-test end points

(500 hours):

V dc

133

---

Ez

-

3347

Ionization voltage (1)

V dc

113

---

Eb

-

3337

Voltage drop (2)

V dc

---

103

Eb

-

3337

Voltage drop (3)

V dc

4.0

---

---

6

3335

Regulation (1)

V dc

2.5

---

---

-

3335

Regulation (2)

---

---

---

---

No voltages

7

1031

Variable-frequency

applied

vibration (Type 0C3W )

V dc

210

---

Ez

Rp/Ib = 5 to

7, 8

3347

Ionization voltage (2)

40 mA dc

(total darkness)

NOTES:

1. Pins 3 and 7 tied internally.

2. Fixed resistors may be used and Ebb varied to give desired current.

3. Test to be conducted with the tube exposed to light intensity of 5 to 50 footcandles.

4. This test to be performed at the conclusion of the holding period.

5. This test applies for flexible leads as well as for rigid leads.

6. The tube shall have reached the end of its life with regard to regulation (1) when that regulation first

exceeds the value of 4.0 volts.

7. This test shall be performed during the initial production and once each succeeding 12-calendar

months in which there is production. An accept on zero defect sampling plan shall be used, with

a sample of three tubes with an acceptance number of zero. In the event of failure, the test will

be made as a part of conformance inspection, part 3, with an acceptance level of 6.5 (see note 9).

The regular "12-calender month" sampling plan shall be reinstated after three consecutive samples

have been accepted.

8. Test to be conducted with the tube under test enclosed in a light tight enclosure composed of a

non-conducting material. Measurements to be performed after the test specimen is held in the

enclosure for 24 hours. The tube shall fire within 15 seconds.

9. This specification sheet uses accept on zero defect sampling plan in accordance with MIL-PRF-1, table III.

3