MIL-PRF-1/1755B

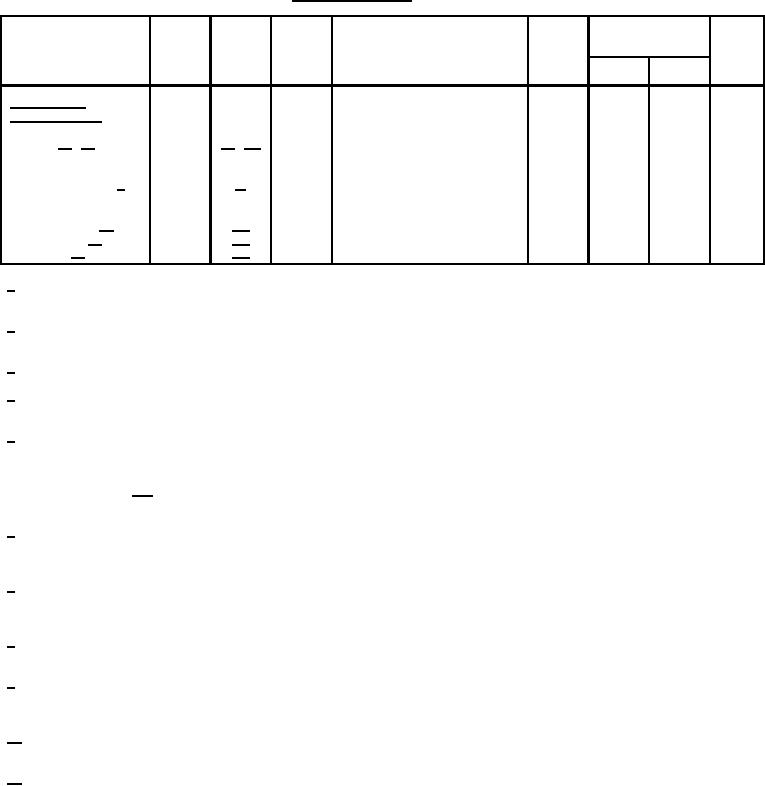

TABLE I. Testing and inspection - Continued.

Limits

Unit

Symbol

Conditions

Test

Notes

Method

Inspection

Min

Max

Conformance

inspection, part 3

hours

---

1,250

29/, 30/

Group D; VSWR = 1.5 cycled

1, 2

Life test 29/ 30/

cycles

---

1,500

through λg every 15 minutes

(approximately)

Life-test end points: 2/

2/

W

---

70

Po

4250

2

Power output

MHz

2.5/tpc

---

BW

4308

1, 2

RF bandwidth 21/

21/

dB

---

6

Ratio

4308

1, 2

Minor lobes 21/

21/

%

0.5

---

MP

4315

2

Stability 17/

17/

1/

Unless otherwise specified, the acceptance level for all tests listed under conformance inspection, part 1, shall be accept on

zero failures.

2/

If during life test, the tube does not meet the specified limits, it shall be recycled for an additional five cycles. At such time, the

tests shall be repeated. The tube will be considered satisfactory if it passes the second test.

3/

The tuning mechanism shall be capable of withstanding a static torque of 75 inch-ounce at the ends of its travel.

4/

The tube shall be capable of normal operation without electrical breakdown with the input bushing in air at normal atmospheric

conditions.

5/

Prior to the application of high voltage, the cathode shall be heated to the required initial operating temperature. This shall be

done by applying 13.75 volts ±5 percent for 150 seconds, minimum. On the application of anode voltage, the heater voltage

shall be reduced in accordance with the following schedule:

Ef = 13.75 (1 - Pi ) ±5 percent; for Pi = 0 to 370 watts; where Pi = epy x Ib.

530

6/

The characteristics of the applied pulse shall be those which result in proper starting and oscillation. The rate of rise of the

voltage pulse, the percentage of pulse voltage ripple, and the rate of pulse voltage fall are among the most important

considerations.

7/

The rate of voltage (rrv) shall be expressed in kilovolts per microsecond (kV/”s) defined by the steepest tangent to the leading

edge of the voltage pulse above the 70 percent amplitude point amplitude point. Any capacitance used in the viewing

(measuring) circuit shall not exceed 6 picofarads (pF).

8/

In handling and mounting the magnetron, care shall be exercised to prevent demagnetization. See figure 1. The use of

magnetic inspection tools is prohibited.

9/

With a total airflow of approximately 20 cfm at approximately 760 mmHg, 25șC divided equally and directed through the cooling

fins toward the body of the tube from two ducts placed 0.750 inch (19.05 mm) maximum from cooling fins, the specified rise

above ambient temperature shall not be exceeded.

10/ Temperature measurements shall be made only after thermal equilibrium has been reached. The frequency shall be measured

at the extremes of any 30șC temperature difference in the specified temperature range.

11/ The tube shall be subjected to five shocks of the specified peak amplitude and duration in each of three mutually perpendicular

directions. Following impact tests, the tube shall show no mechanical failure and shall meet the power output and pulse voltage

requirements of conformance inspection, part 1.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business