MIL-PRF-1/1738D

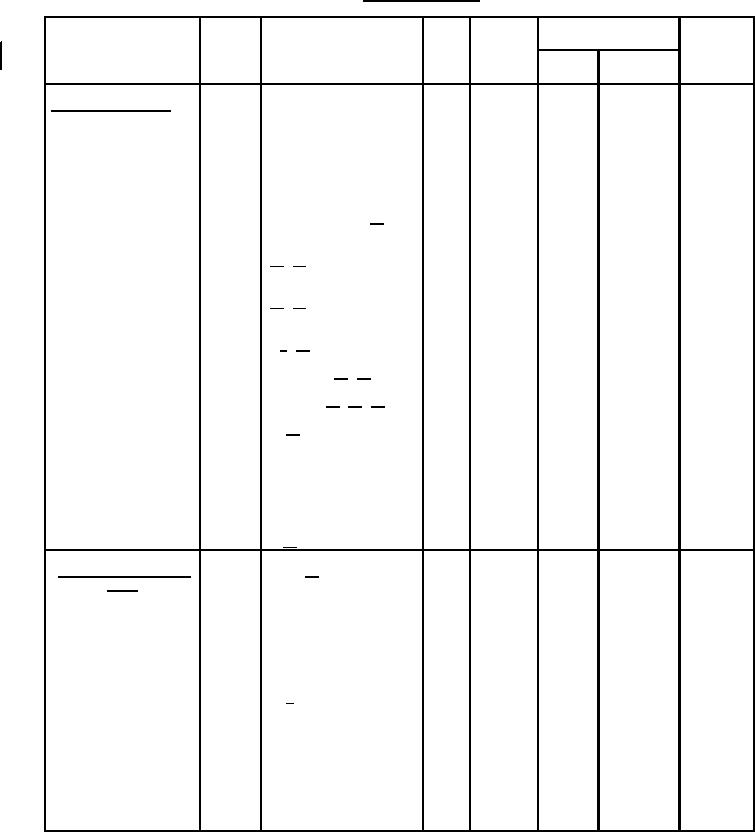

TABLE I. Testing and inspection.

Inspection

Method

Conditions

Test

Symbol

Limits

Unit

MIL-STD-

1311

Min

Max

Qualification inspection

4223

Torque

T (body) = -55°C

nonoperating to +130°C

operating

Starting

2

---

---

12

inch-ounces

Operating

2

---

---

10

inch-ounces

Mechanical tuning fatigue

4223

No voltages applied 12/

---

---

50,000

---

cycles

Low-frequency vibration

1031

No voltages applied

---

---

---

---

---

13/ 14/

High-frequency vibration

1031

No voltages applied

---

---

---

---

---

13/ 14/

Temperature coefficient

4027

1

---

0.25

ĆF/ĆT

MHz/°C

F = F2; T = 70°C to 130°C

3/ 15/

Shock, specified pulse

1042

Condition J

14/ 16/

---

---

---

---

---

Salt spray (corrosion)

1006

Method B

17/ 18/ 19/

---

---

---

---

---

Life test

4551

26/

---

t

2,000

---

hrs

Life test end points:

---

Power output

4250

1

Po

80

140

W

RF bandwidth

4308

1

BW

---

2.5/tpc

MHz

Minor lobe ratio

4308

1

---

6

---

dB

Stability

4315

t = 180 seconds

1

MP

---

0.5

%

Resettability

4223

27/

1

---

15

MHz

ĆF

Conformance inspection,

20/

part 1

---

---

---

---

---

45 psia minimum, input and

Pressurizing

4003

output

Heater current

4289

Ef = 13.75 V

---

If

2.9

3.3

A

(nonoperating)

W armup time

4303

1/

1, 2

---

---

---

---

Pulse voltage

4306

---

epy

23

27

kV

Power output

4250

1

Po

100

140

W

RF bandwidth

4308

1

BW

---

2.0/tpc

MHz

Minor lobe ratio

4308

1

---

10

---

dB

See footnotes at end of table.

2

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business