MIL-PRF-1/1725B

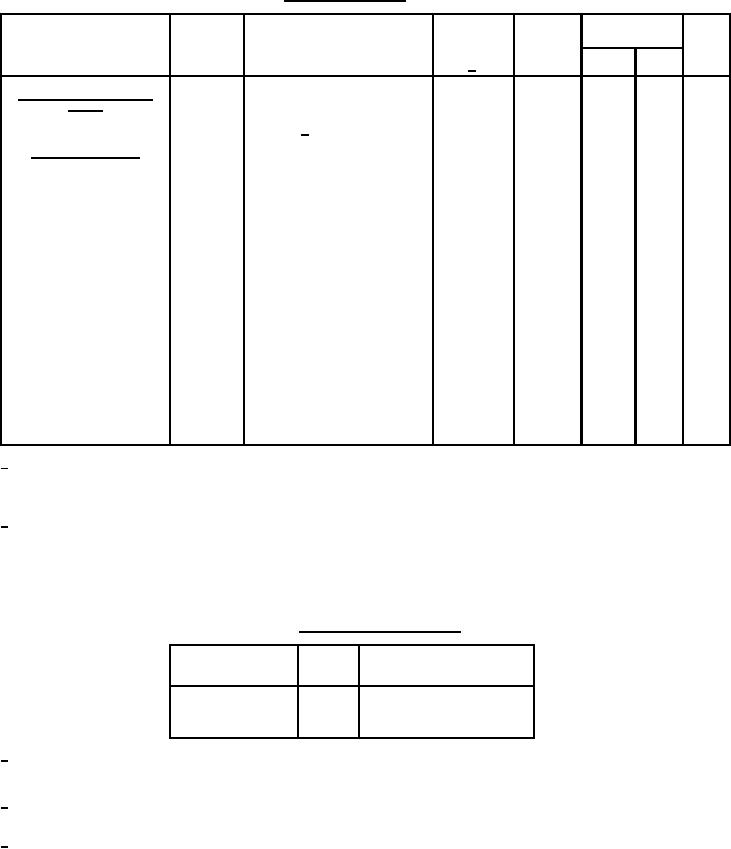

TABLE I. Testing and inspection - Continued.

MIL-STD-

Inspection

1311

Conditions

Acceptance

Symbol

Unit

Limits

Method

Level

5/

Min

Max

Conformance inspection,

part 3

----

----

----

----

----

Service-life guarantee

1/

----

Periodic-check tests

----

----

----

----

----

No voltage applied;

Shock, specified pulse

1042

acceleration = 15 G peak (min);

shock = 11 ms half-sine;

total impact = 6

(3 each X and Z axes)

Shock, specified pulse

end points:

V dc

-127

-95

Ec1

----

Electrode voltage (grid)

1261

-25

----

Ic1

----

1266

Total grid current

µA dc

----

----

----

----

No voltage applied;

1032

Vibration, mechanical

----

accel = 2 G peak (min);

F = 10 to 50 Hz, ascending only;

sweep t = 3 to 8 minutes; 1 sweep

each X and Z axes

Vibration mechanical

end points:

-127

-95

Ec1

----

1261

Electrode voltage (grid)

V dc

-25

----

Ic1

----

1266

Total grid current

µA dc

1/

The tube manufacturer warrants the tube for one year from the date of shipment, or 1,000 hours of filament life, whichever

first elapses. This warranty applies only when the tube is operated within the maximum ratings (see "Absolute ratings" of

MIL-PRF-1). A defective tube shall either be replaced, or at the option of the manufacturer a credit shall be made in the

amount of the original purchase price prorated on the basis of 1,000 hours of "filament-on" time.

2/

Minimum airflow requirements for incoming air at 40°C maximum at sea level, for operation below 30 MHz, are shown in table

II. Additional cooling may be required for operation above 30 MHz. In all applications, an air-system socket, such as the

EIMAC SK-1400 with air chimney such as the EIMAC SK-1406, or equivalents, should be used. Air should be directed in a

base-to-anode direction, and the values shown are for the tube and the SK-1400/SK-1406 combination with the air so

directed. In all cases, enough air should be used to prevent operation with the anode core and seal temperatures above the

maximum rating, and where long life and consistent performance are factors, cooling in excess of minimum requirements is

normally beneficial. Air should be applied before or simultaneously with the application of filament voltage, and may be

removed simultaneously with the electrode voltages.

TABLE II. Minimum airflow requirements.

Approximate pressure drop

Airflow

Anode dissipation

(in. H20)

(cfm)

(watts)

0.3

36.5

1,500

0.8

60

2,500

1.6

86

3,500

3/

During continuous Class AB1 operation, it is not likely that the absolute maximum ratings for the anode voltage (Eb) and

anode current (Ib) can be used simultaneously, as efficiency would have to be very high (75 percent) in order to avoid

exceeding the anode dissipation (Pp) rating of 3.5 kW.

4/

In all electrical tests involving application of filament voltage, an air-system socket and chimney may be used and forced-air

cooling is permissible.

5/

This specification sheet uses accept on zero defect sampling in accordance with MIL-PRF-1, table III.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business