MIL-PRF-1/1718A

Dimensions

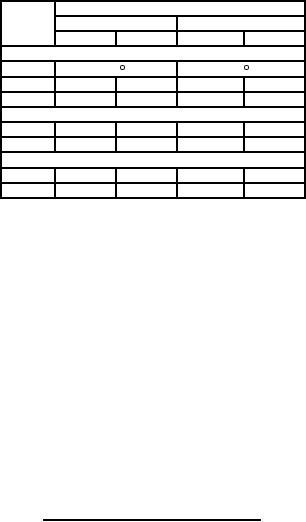

Ltr

Inches

Millimeters

Min

Max

Min

Max

First article sample inspection

A

22

23

E

.235

.265

5.97

6.73

F

---

4.000

---

101.60

Conformance inspection, part 1

C

.256

.261

6.50

6.63

D

3.469

3.531

88.11

89.69

Conformance inspection, part 2

B

5.297

5.327

134.54

135.31

G

4.745

4.755

120.52

120.78

NOTES:

1. The waveguide flanges of the TR tube shall be cold rolled steel.

2.

All external and interface surfaces of the TR tube, with the exception of the aluminum parts, shall be corrosion

protected using cadmium plate in accordance with Federal Specification QQ-P-416, type II, class 1, or

equivalent. Aluminum parts shall have a chemical film finish in accordance with MIL-PRF-5541 or equivalent..

All external surfaces with the exception of the mating surfaces of the waveguide flanges shall be wash primed

in accordance with MIL-PRF-8507 one coat .0002 inch (0.005 mm) to .0005 inch (0.013 mm) thick with primer

in accordance with MIL-PRF-15328 or equivalent. Paint two coats .001 inch (0.03 mm) thick with gray enamel

in accordance with MIL-PRF-15090, type II, class 2 ,or equivalent.

3.

The rf input and output shall be marked as indicated.

4.

The rf input and output flanges shall mate with M3922/61-1.

FIGURE 1. Outline drawing of electron tube type 8922 - Continued.

Custodian:

Preparing activity:

Army - CR

DLA - CC

Navy - EC

Air Force - 85

(Project 5960-3484)

Review activities:

Army - AR, MI

Navy - AS, CG, MC, OS

Air Force - 99

6