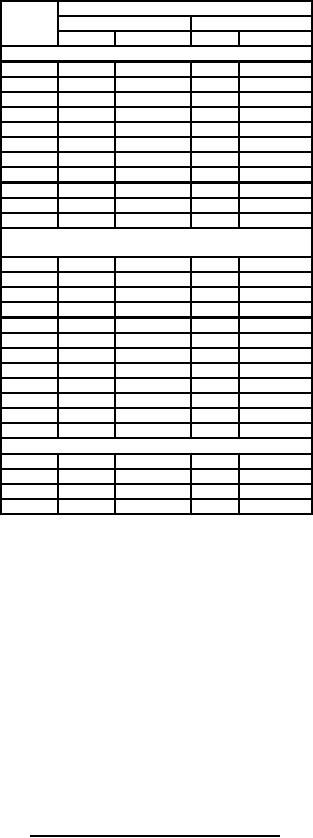

MIL-PRF-1/1633B

Dimensions

Ltr

Inches

Millimeters

Min

Max

Min

Max

Conformance inspection, part 2

A

1.815

1.875

46.10

47.63

B

---

1.534

---

38.96

C

---

1.475

---

37.47

D

1.289

1.329

32.74

33.76

F

.970

1.010

24.64

25.65

G

.462

.477

11.73

12.12

J

.766

.826

19.46

20.98

N

1.025

1.035

26.04

26.29

R

.655

.665

16.64

16.89

T

.213

.223

5.41

5.66

U

.315

.325

8.00

8.26

Conformance inspection, part 3

(periodic check) (see note 2)

E

.125

.185

3.18

4.70

H

---

.040

---

1.02

K

.025

.046

0.64

1.17

L

1.234

1.264

31.34

32.11

M

1.180

1.195

29.97

30.35

P

.772

.792

19.61

20.12

Q

.650

.850

16.51

21.59

S

---

.545

---

13.84

V

---

0.086

---

2.18

W

---

.100 RAD

---

2.54 RAD

X

---

035 RAD

---

0.89 RAD

Y

.105

.145

2.67

3.68

Electrode contact areas (see note 12)

AA

.035

.361

0.89

9.17

AB

1.185

1.265

30.10

32.13

AC

1.534

1.728

38.96

43.89

AD

1.475

1.815

37.47

46.10

NOTES:

1. Insulation material between heater and heater-cathode shall be securely affixed.

2. These dimensions shall be tested on 10 tubes per month when in continuous production. Failure of more than

one tube to meet tolerances for any dimension shall cause that dimension to become, for all lots in process,

part of conformance inspection, part 2.

3. Silver plated 30 MSI minimum. Note 2 shall apply.

4. Plating not required over radiator and radiator support of copper, aluminum, or approved equivalent.

5. This surface shall be used for measurement of anode shank temperature.

6. Holes for tube extractor through top fin only.

7. Inner edge of heater and outer edge of cathode rf connection shall be free from burrs and sharp edges.

FIGURE 1. Outline drawing of electron tube type 7211 - Continued.

8

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business