MIL-PRF-1/1618C

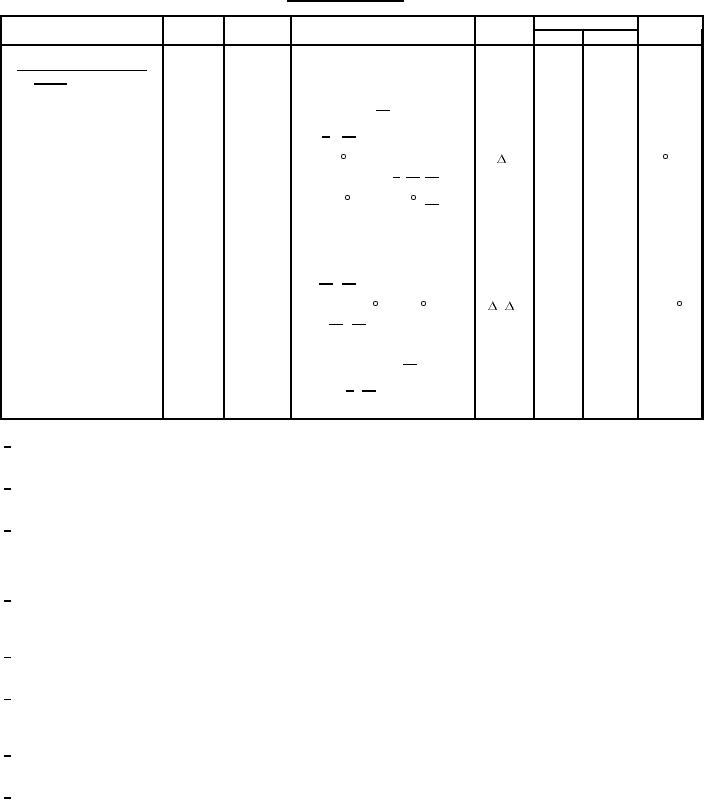

TABLE I. Testing and inspection - Continued.

Limits

Inspection

Method

Test

Conditions

Symbol

Min

Max

Unit

Conformance inspection,

part 3 - Continued

High frequency vibration

1031

No voltages

12/

---

---

---

---

Shock

1041

8/ 12/

---

---

---

---

Air cooling

1143

2

---

TA+50

TA = 50 C (max)

T

C

Pi - Po = 150 W 9/ 12/ 14/

Tuner operating torque

4223

Torque

---

32

inch-

TA = -55 C and +125

12/

ounce

Anode-cathode cap

---

C

4.0

8.0

pF

capacitance

Mechanical fatigue

4223

10/ 12/

N

2,500

---

cycles

Temperature coefficient

4027

4

---

0.25

T(anode) = 70 C to 100 C

F/ T

MHz/ C

12/ 14/

Barometric pressure

1002

Pressure = 349 mmHg

---

---

----

---

reduced

F = 9,160 MHz

12/

Low temperature

1047

4

Stability 7/ 12/

MP

---

2

%

operation

1/

Unless otherwise specified, the acceptance level for all tests listed under conformance inspection, part 1, shall be 1.0 percent with

inspection level of II.

2/

Unless otherwise specified, the acceptance level for all tests listed under conformance inspection, part 2, shall be 6.5 percent with

inspection level of S3.

3/

The magnetron may be coupled directly to a RG-51/U waveguide in accordance with MIL-W-85, with a UG-52B/U chock flange in

accordance with MIL-PRF-3922/25. However, for a minimum VSWR of this coupling, it is recommended that a specially designed

choke flange be used which mates with the angular RG-51/U output of the magnetron to provide a straight section of RG-51/U

waveguide through the coupling network.

4/

Immediately after the holding period, and after a 120-second preheat, the pulse voltage as specified in conformance inspection, part

1, shall be instantaneously applied and the magnetron missing pulse count shall not exceed 1 percent over the first minute of

operation.

5/

The RF bandwidth shall be within the limits specified when a VSWR of 1.5 is introduced in the load at a distance no greater than

0.197 inches (0.5 meters) from the magnetron coupling flange, the phase being adjusted for the worst spectrum.

6/

When the direction of tuner drive is reversed at the frequency specified, the magnetron shall not continue to tune in the original

direction by more than the specified frequency increment before reversing. Test to be performed at 9,000 MHz, and 9,080 MHz,

and 9,160 MHz.

7/

Stability shall be measured with the VSWR adjusted to the phase which produces maximum instability. The missing pulses shall be

counted during any 3 minute period of a test interval not to exceed 6 minutes.

8/

The tube shall be subjected to five shocks of peak amplitude duration in accordance with MIL-STD-202, method 213, test condition

G. Following the shock test, the tube shall show no mechanical damage, and shall pass the power output and pulse voltage

requirements of conformance inspection, part 1.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business